Conversion project of the Campus Week 2025

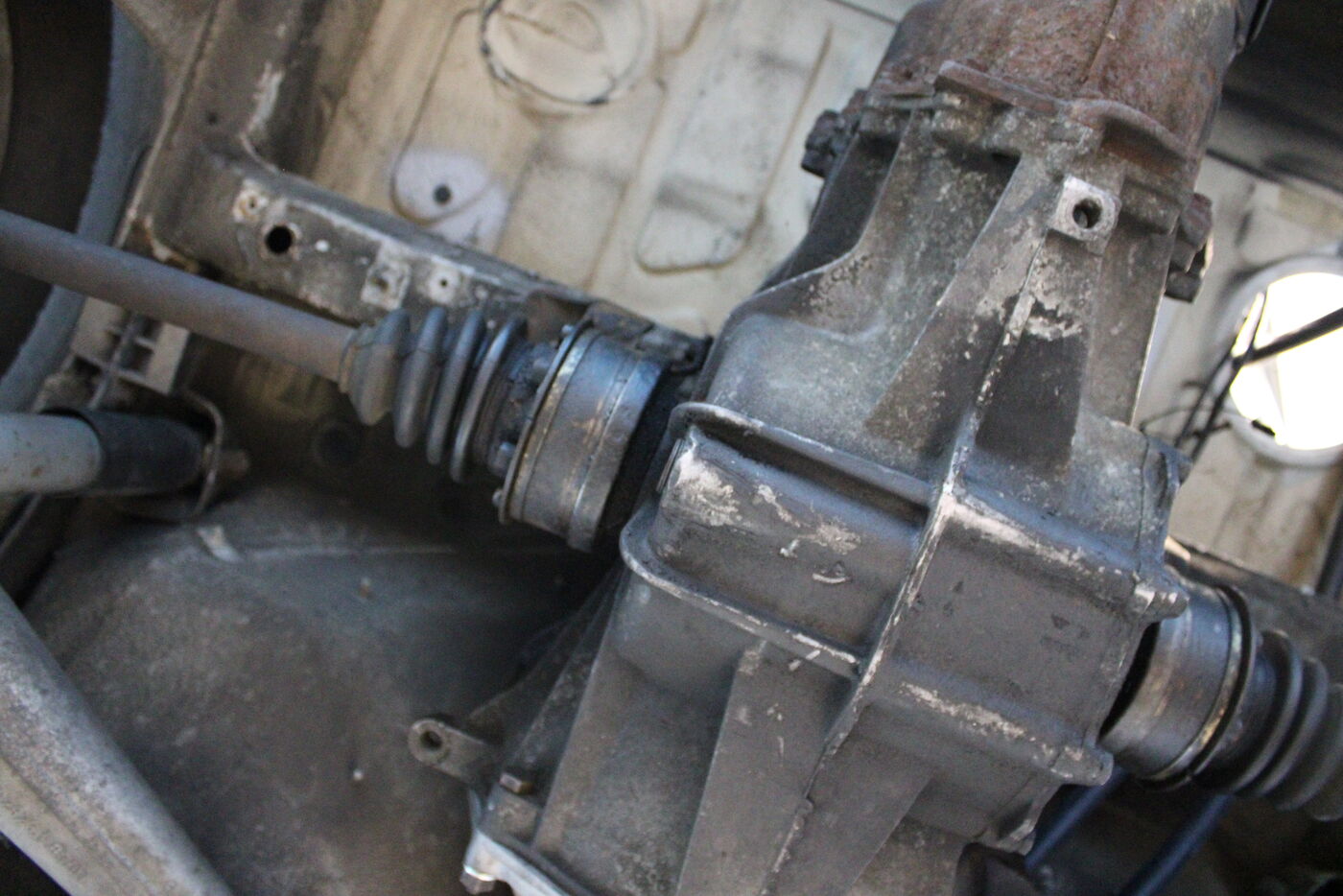

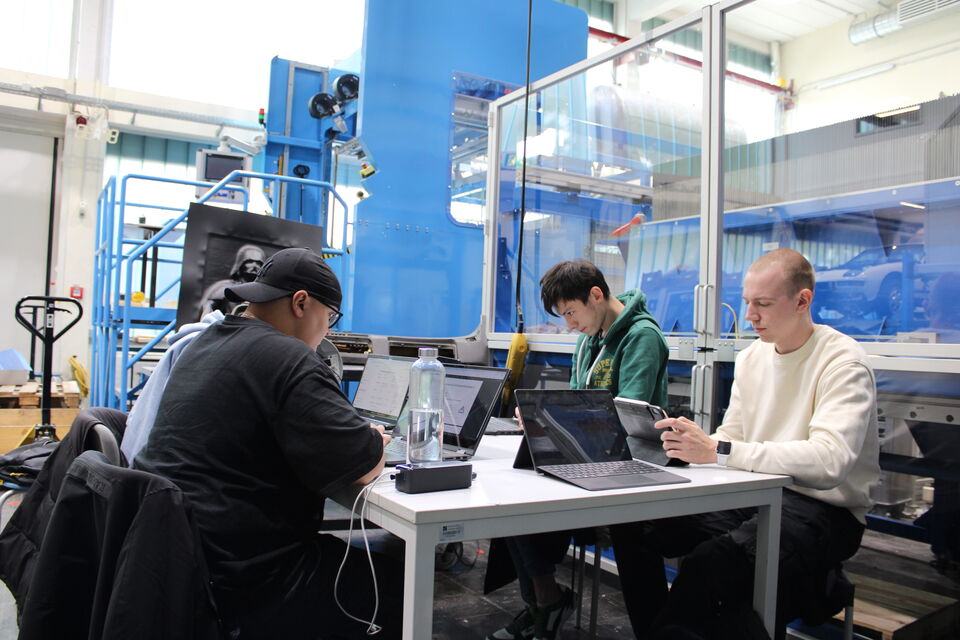

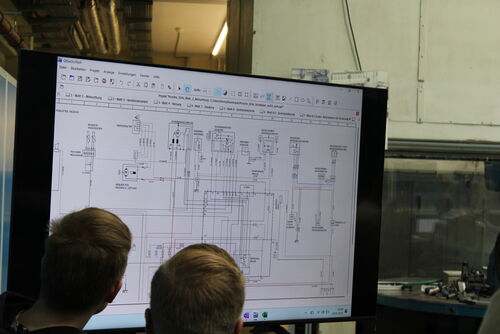

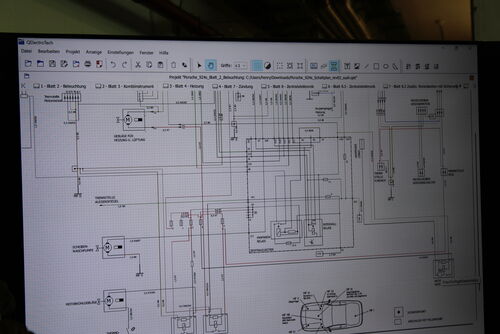

The Hochschule Niederrhein's interdisciplinary "Porsche 924S electric conversion" project combines tradition with innovation. During the current Campus Week 2025, students from various faculties are working together to convert a classic Porsche 924S into a fully electric vehicle. This project builds on the experience gained during Campus Week 2024.

Interestingly, the very first vehicle developed by Ferdinand Porsche in 1898 was already electrically powered - a remarkable historical detail that lends this conversion project a special significance.