NRW Minister Pinkwart visited our state-of-the-art chemistry lab at the Hochschule Niederrhein on Sept. 30

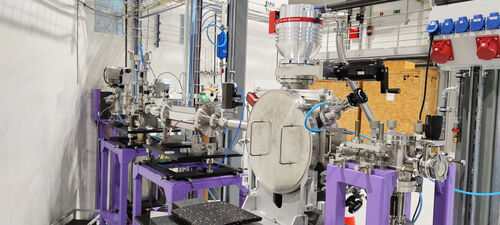

Prof. Dr. Andreas Pinkwart, Minister for Economic Affairs, Innovation, Digitalization and Energy of the State of North Rhine-Westphalia, visited the chemistry lab at HIT (Institute for Surface Technology) at Hochschule Niederrhein on Thursday, September 30. Prof. Dr. Dr. Alexander Prange (Vice President Research and Transfer), Prof. Dr. Stegemerten (Vice President Studies and Teaching Education) and Institute Director Prof. Dr. Jost Göttert received the minister at Adlerstraße in Krefeld. The intelligent high-throughput facility at HIT paves the way for the digital future of chemistry.

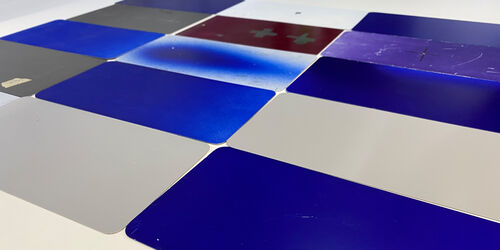

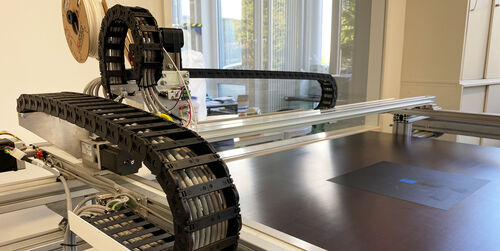

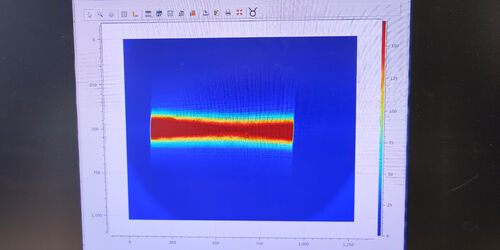

"The use of artificial intelligence enables sustainable and precise development of new products. This resource-saving approach is fascinating," said Prof. Dr. Andreas Pinkwart following the tour. The high-throughput facility is intended to develop new formulations for paints, coatings and adhesives not only faster than before, but above all more sustainably with properties optimally adapted to the respective application.

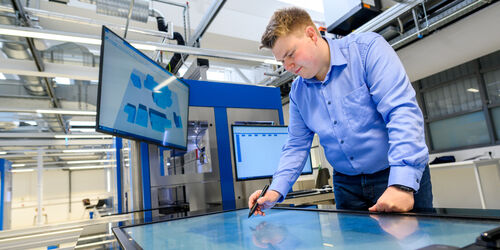

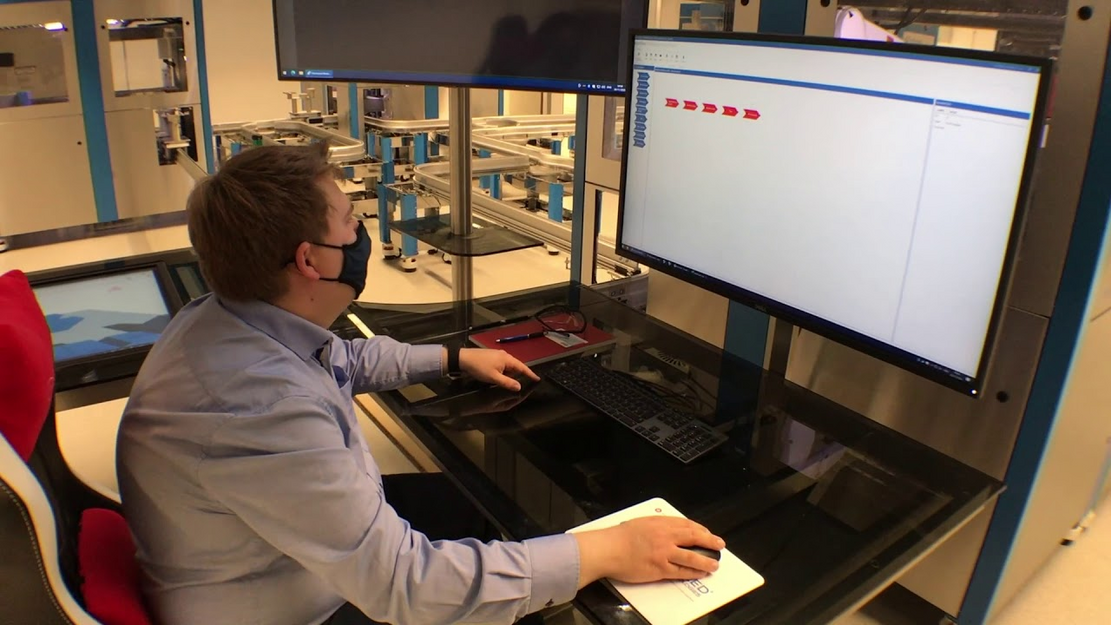

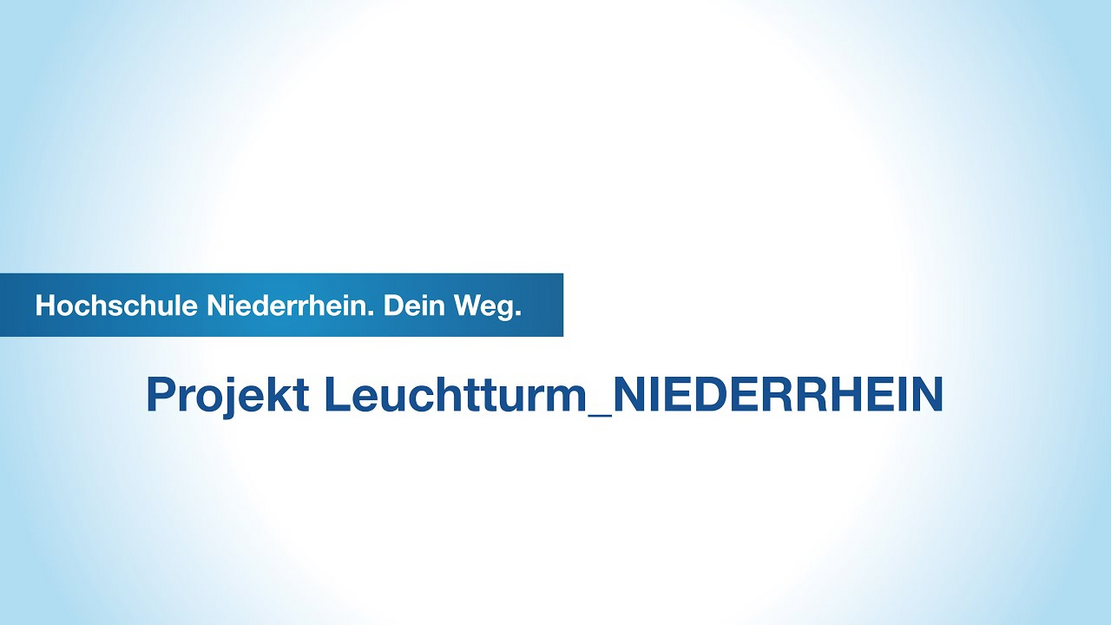

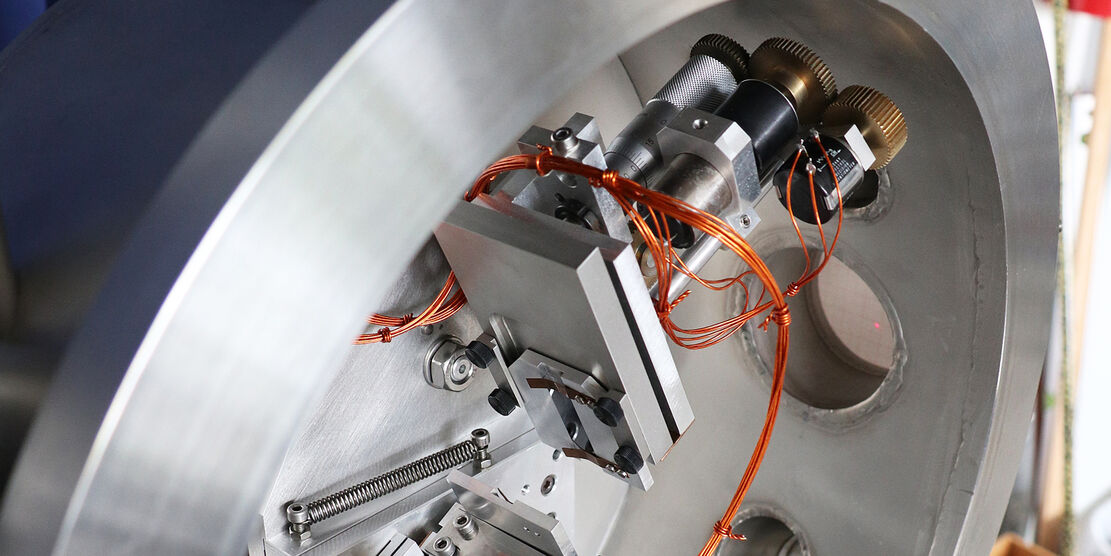

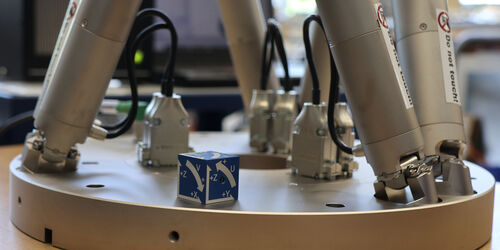

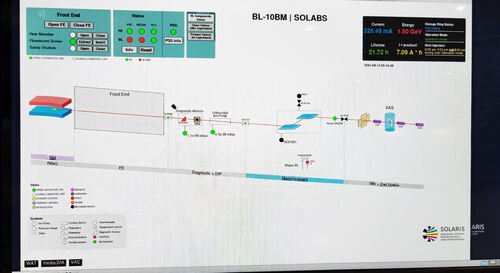

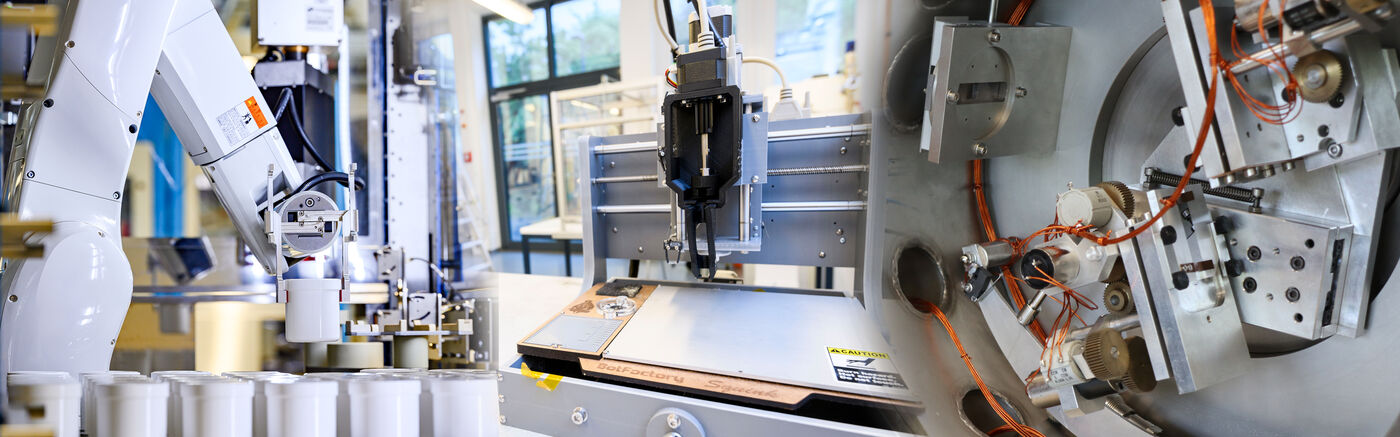

"With the HIT, we are launching into the digital future of chemistry. It makes us proud to be able to present this," explains Professor Dr. Jost Göttert. While chemists work on how renewable raw materials can be formulated into innovative products and for new applications, routine laboratory tasks will be handled by an automated, intelligently controlled system of robots. Small and medium-sized companies in the region are thus given the opportunity to use the possibilities of digitalization and Industry 4.0 for the development of their innovative products.

The facility, located in Krefeld at Campus West, was realized as part of the INTERREG project D-NL-HIT - a cross-border project with participants from the German-Dutch border region, with a total volume of 10.3 million euros, and is the largest externally-funded project from research and transfer for the Hochschule Niederrhein to date. The facility is capable of performing up to 100 experiments per day. However, the aim is to use machine learning to develop new products quickly and with high quality using as few experiments as possible, i.e. with a low consumption of chemicals.

In the HIT, Mr. M.Eng. Lasse Wagner as one of our cooperation managers from the project Leuchtturm_NR (Innovative Hochschule) and is the link between the business contacts of the SMEs and the HIT Institute at the Hochschule Niederrhein.

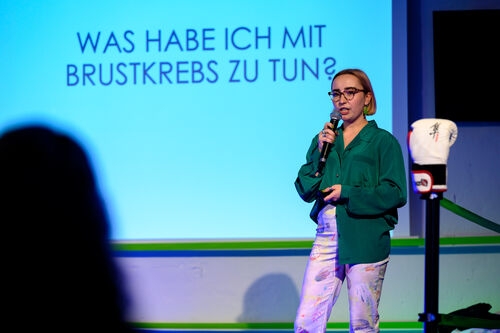

In the course of the minister's visit, The Hochschule Niederrhein used the occasion to have an image film produced for the Leuchtturm_NR project. With the support of WDR presenter Dieter Könnes, numerous voices from politics, business and students were captured in order to use them for the future communication of the USPs of the HIT.

Cooperation Management

Cooperation Management