Can used textiles be recycled? In most cases, they end up as cleaning rags or insulation material (downcycling) rather than new clothing or bedding (recycling). Much research still needs to be done for fiber-to-fiber recycling.

The Hochschule Niederrhein (HSNR) and other cooperation partners are now tackling precisely this task in the sponsor project "KICKup" (AI-supported, chemical cellulose cycles). The university's own Research Institute for Textile and Clothing (FTB) is specifically addressing the quality of used textiles.

The project focuses on inventing a system that automatically sorts used textiles according to material composition using artificial intelligence (AI). The Deutsche Bundesstiftung Umwelt (DBU) is sponsoring this research with almost 400,000 euros. Around 100,000 euros of this will go to The Hochschule Niederrhein.

The impetus for this came from the textile service company Dibella. Here, a model is being investigated as to how table and bed linen from restaurants, hotels or hospitals can be assigned to a suitable fiber recycling process at the end of their product life, depending on the cotton or polyester content. As with waste separation, the more precisely the fabrics are differentiated, the better they can be returned to the textile cycle and reused for new products.

Up to now, everything has been sorted by hand in the large laundries. This takes a lot of time and is a difficult task because of the quantity and the variety of fabrics that cannot be seen with the naked eye. So how would it be if artificial intelligence and modern technology accurately analyzed the old textiles and an automatic separation system took over the work?

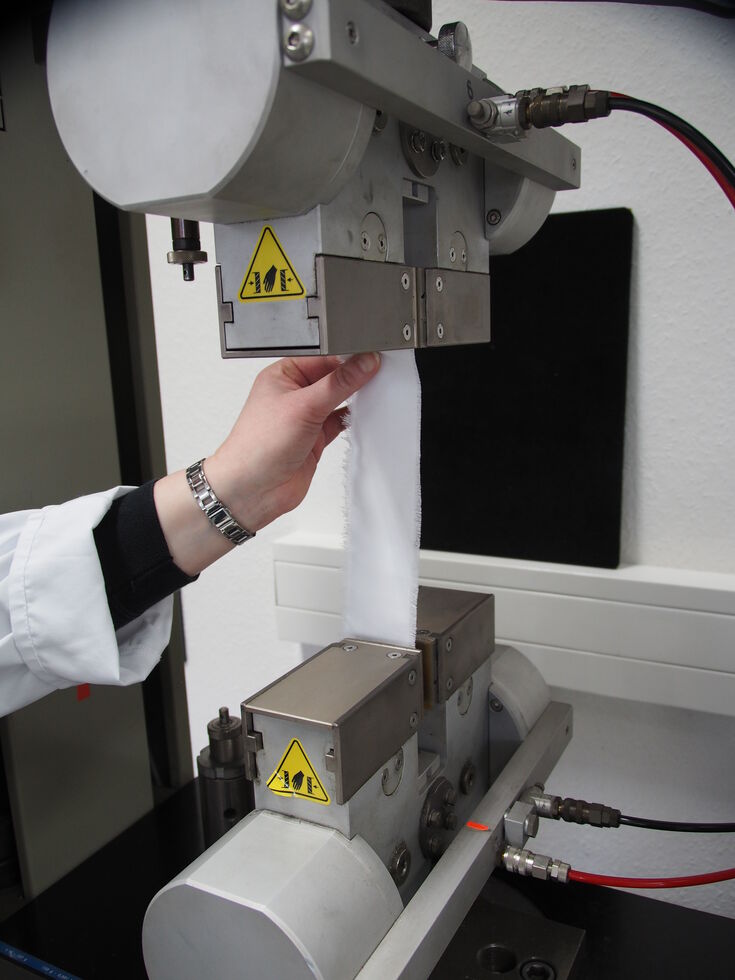

This is the question that Dibella and other partners have taken up. The FTB's task here is chemical quality assessment: it analyzes whether used textiles and those discarded from rental services made of cotton or their regenerated fibers or cotton-polyester blended fabrics are still in good enough condition to be recyclable. Specifically, only white fabrics from industrial laundries will be studied for the project initially.

In the next step, the system to be designed will use near-infrared technology and AI to record and recognize the structure and composition of the textiles and sort them with high separation accuracy. If cotton and polyester fibers are then separated from each other, the cellulose pulp (cellulose) obtained from the cotton portion can be recycled for new regenerated cellulose fibers and used in new textiles if the fiber quality is sufficient.

"Our goal is also to investigate and evaluate the repeated recyclability of used textiles with portions of cotton regenerated fibers with regard to a completely closed-loop system," said Professor Dr.-Ing. habil. Maike Rabe. She is the project leader at HSNR. "If necessary, we will develop new improved design-for-recycling approaches in material composition and fabric construction for the recyclable textile articles for this purpose."

As the project progresses, a logistical storage system for the sorted laundry will also be created as a prototype.