Fraunhofer IML opens the Textile Logistics Center with The Hochschule Niederrhein

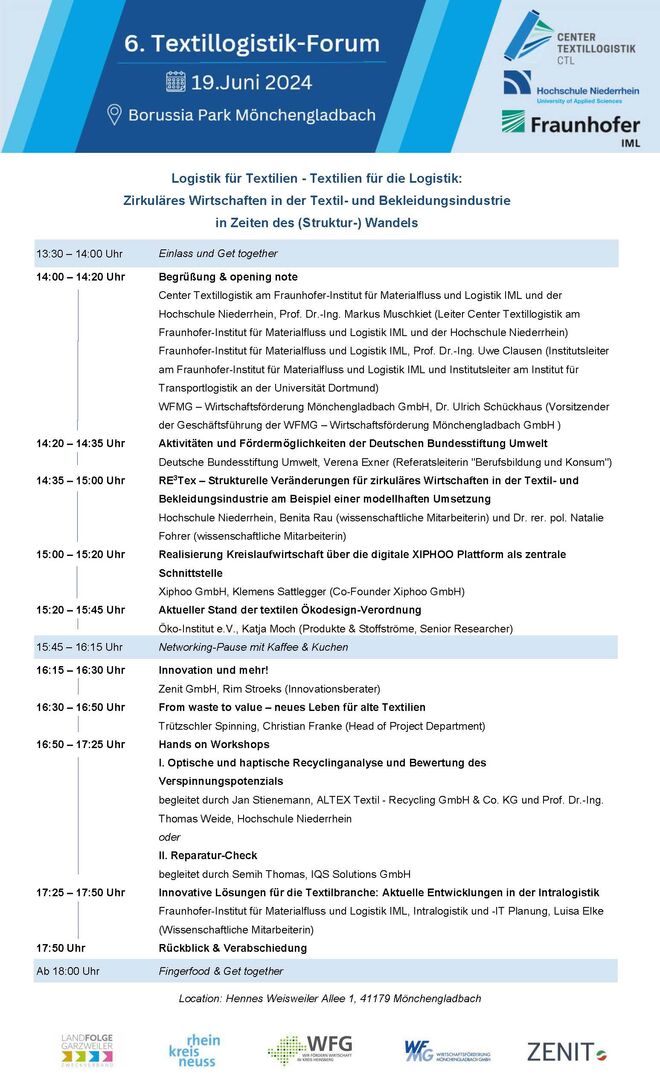

Mönchengladbach, October 22. The Center Textile Logistics (CTL) was opened today in the new Textile Academy on the Mönchengladbach campus of The Hochschule Niederrhein. The CTL is intended to be a driver of innovation for the region's textile industry. It was founded last year in cooperation with The Hochschule Niederrhein and the Fraunhofer Institute for Material Flow and Logistics IML.

University President Prof. Dr. Hans-Hennig von Grünberg opened the launch event with the words: "It is our declared goal to be perceived as the nationwide central training partner and innovation driver for the textile industry. With the founding of the Fraunhofer Center Textile Logistics, we have come a good deal closer to this goal. Today, it is hard to imagine a textile company not knowing us."

The new center is part of a textile portfolio at The Hochschule Niederrhein that is unique in Germany. In addition to the Faculty of Textile and Clothing Technology, the largest of its kind in Europe, this includes: the Research Institute for Textile and Clothing (FTB), the German Textile Research Center Northwest (DTNW) operated jointly with the University of Duisburg-Essen, training and continuing education as part of the Textile Academy together with two textile associations, two public testing centers for textile material testing of textiles and the Innovatorium, which is being created as part of the "Innovative University" excellence competition of the Federal Ministry of Education and Research.

"The textile and clothing industry was already living globalization before the term even existed," said Dr. Wilfried Holtgrave, President of the Association of the Northwest German Textile and Clothing Industry. "Today, logistics has become a decisive success factor in the textile and clothing industry. High-performance textiles are seen as a key technology for future logistics and mobility." Rapid seasonal changes, a high import quota, many returns in online retail and other aspects mean that logistics is becoming increasingly important for textile companies. Companies are to be supported by the new center on a scientific level.

Rolf Königs, President of the Rhineland Textile and Clothing Industry Association, explained the inseparable unity of development, production and logistics along the entire value chain. "Textile logistics in particular has developed enormously and gained in importance in Germany and especially in the region in recent years. The timing, partners and location for the opening of the Center Textile Logistics (CTL) are a perfect match."

Prof. Dr.-Ing. Uwe Clausen, Director of Fraunhofer IML, said on the occasion of the opening: "For us logistics experts, the textile industry is very exciting due to its specific requirements and its dynamics. With the CTL in Mönchengladbach, we now want to take the opportunity to combine our ideas and textile expertise at the site for the benefit of our customers."

At least eleven people, from student assistants to academic staff, will conduct research and work on industrial projects for the CTL as it is established. The Hochschule Niederrhein will receive start-up funding for the CTL from the Ministry of Culture and Science of the state of North Rhine-Westphalia, which is expected to amount to around one million euros until 2021.

The Fraunhofer IML will receive a grant of one million euros until 2022 as part of the Fraunhofer cooperation program with universities of applied sciences, after which the Center Textile Logistics will finance itself by attracting industry and research funding and thus become a permanent part of Fraunhofer, the university, the city and the region.

Head of the newly created center is Prof. Dr.-Ing. Markus Muschkiet, Professor of Textile Logistics at the Faculty of Textile and Clothing Technology at Hochschule Niederrhein. He sees his task as bringing together the topics of logistics and textiles. To this end, the newly created Center for Textile Logistics draws on the expertise of the Fraunhofer IML in Dortmund in the field of logistics and the expertise of the Faculty of Textile and Clothing Technology at Hochschule Niederrhein in the field of textiles.