In the project "Electrochemical oxidation on boron-doped diamond electrodes for the treatment of electroless nickel baths", a pilot plant is to be set up as part of an upscaling to oxidize hypophosphite and phosphite electrochemically to phosphate. Hypophosphite is a component of the baths, while phosphite is a by-product of electroless nickel plating, a process known as electroless plating.

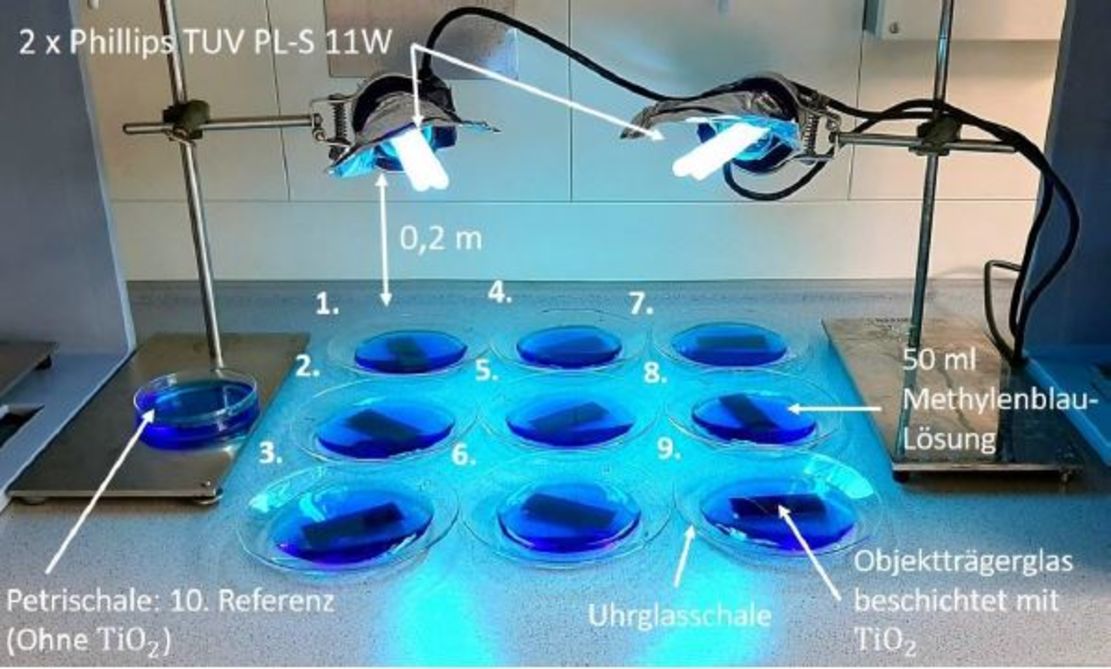

For economic and ecological reasons, the disposal of spent solutions from the process of electroless plating is the focus of the platers. Likewise, the purification of wastewater has gained in importance. If phosphorus species get into the environment, this leads in most cases to above-average growth of plants, the so-called eutrophication. For this reason, The Hochschule Niederrhein is working within the project 'Elimination of phosphite in wastewater from the coating industry' on the treatment of wastewater and spent baths generated by the coating process 'electroless nickel'. A treatment technology patented by the university is available for this purpose (DE102012100481, rod bundle electrode). The main focus of the work is on the elimination of the heavy metal nickel and the oxidation of the phosphorus species to phosphate.

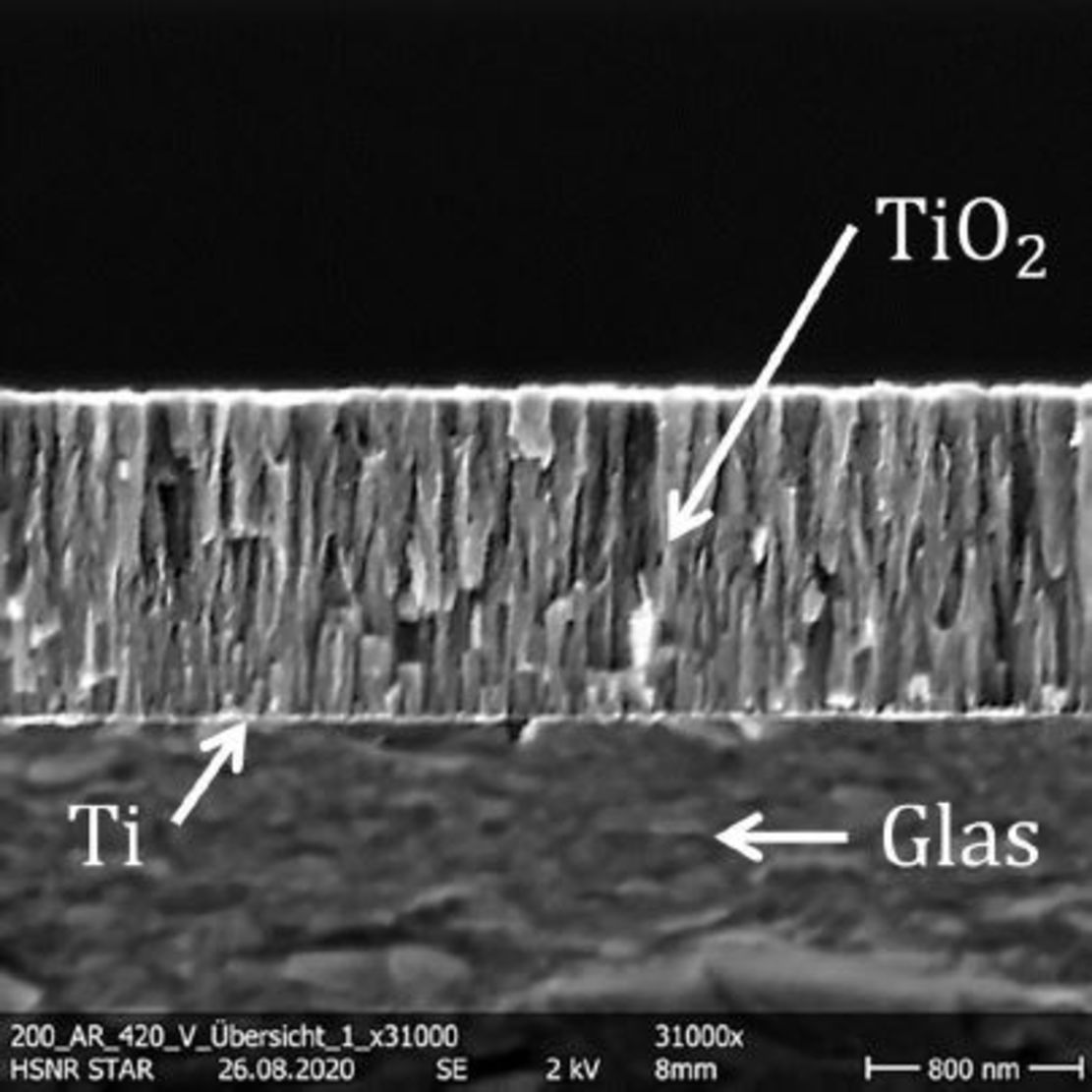

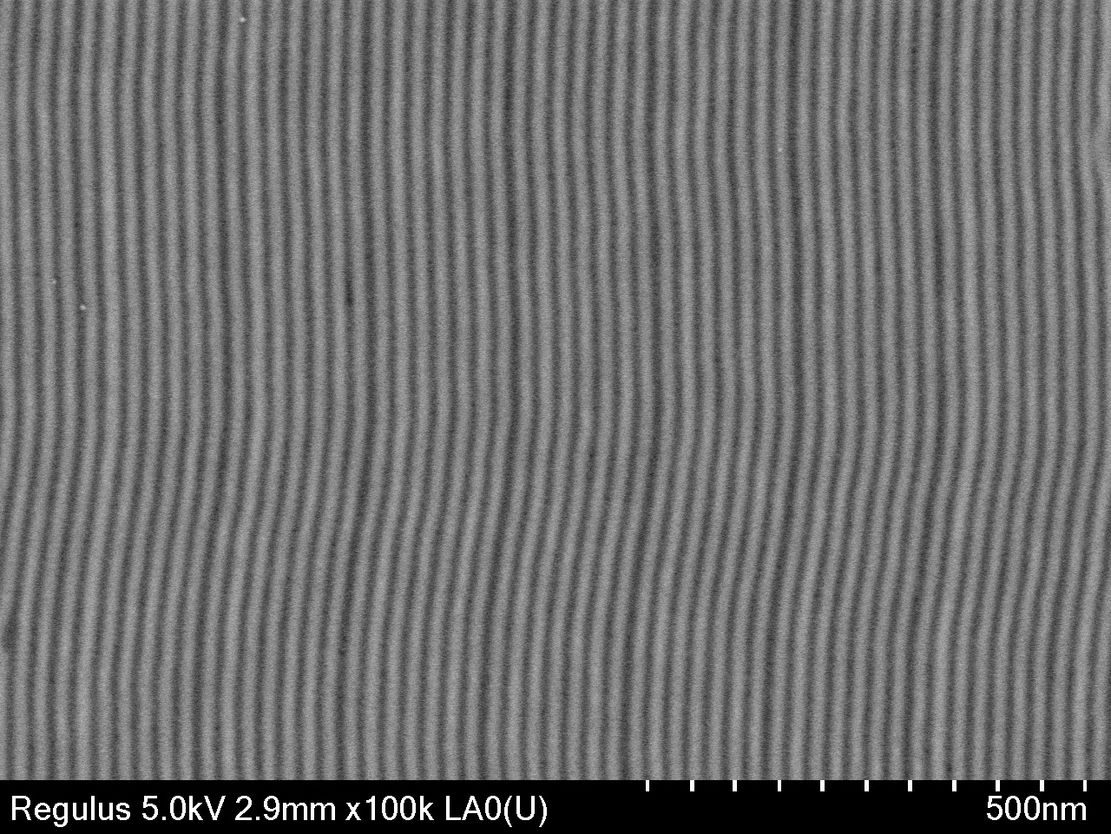

The rod bundle electrode and the electrochemical processes taking place are suitable for increasing the oxidation state of phosphorus when conventional methods fail. The rod bundle electrode works particularly well in the range of low concentrations. Phosphorus species present in the electroless nickel bath are oxidized to phosphate at a boron-doped diamond (BDD) rod bundle electrode. The anodic oxidation of hypophosphite (H2PO2-) and phosphite (HPO32-) to phosphate (PO43-) takes place at the electrode surface. The biggest advantage of the rod bundle electrode, compared to the conventional plate electrodes, is the relatively large surface area. To avoid a back reaction of the phosphate, a shielding of the bath on the cathode side by a diaphragm is necessary. The experiments show that the current density, the volume current, the bath composition and the electrolysis time in the cell have an influence on the phosphorus conversion.