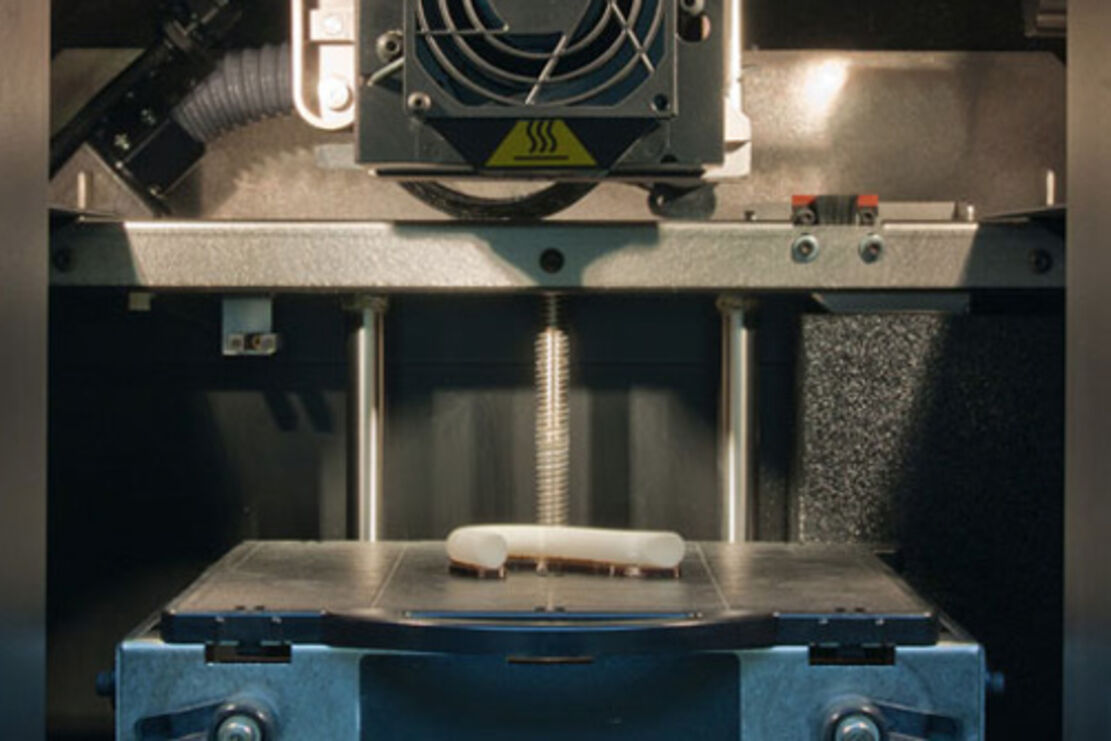

3D printing enables students to print models as objects using data sets. The fused deposition modeling (FDM) manufacturing process is classified as a 3D printing process, even though it ranks independently in the classification of rapid prototyping technologies. The fused deposition process allows an object or model to be built up layer by layer from a fusible plastic. For this purpose, the model material, a thermoplastic, is heated to an extrusion-capable temperature (270°C) and glued in layers (comparable to a hot glue gun). During subsequent cooling, the material hardens again.

The 3D data material that can be processed by the machine (type Dimension Elite from the manufacturer Stratasys) or its control software corresponds to the STL format. However, it is better to use geometry data that is not yet faceted and that is converted on site to prevent design flaws or misunderstandings (e.g., 3DM, IGS/IGES, STP/STEP, DXF and DWG).

Equipment:

Printer: DIMENSION Elite

Process: Fused-Deposition Modeling (FDM)

Build volume: 203 x 203 x 305 mm

(individual parts/segments can also be easily glued together for larger objects)

Layer thickness: 0.1785 or 0.254 mm

Material: ABS (acrylonitrile butadiene styrene)