In the Metal Model Making Workshop, students are taught the practical and technical knowledge and skills of metal technology and metal materials science. The metal model workshop offers the best opportunities to realize experiments, working models, functional models and prototypes in metal construction. For the realization of their designs, the students receive professional support and guidance, which can lead to the ability to work independently on a variety of machines. Here, models and model elements are created for ongoing courses in foundation and advanced courses as well as projects.

Equipment:

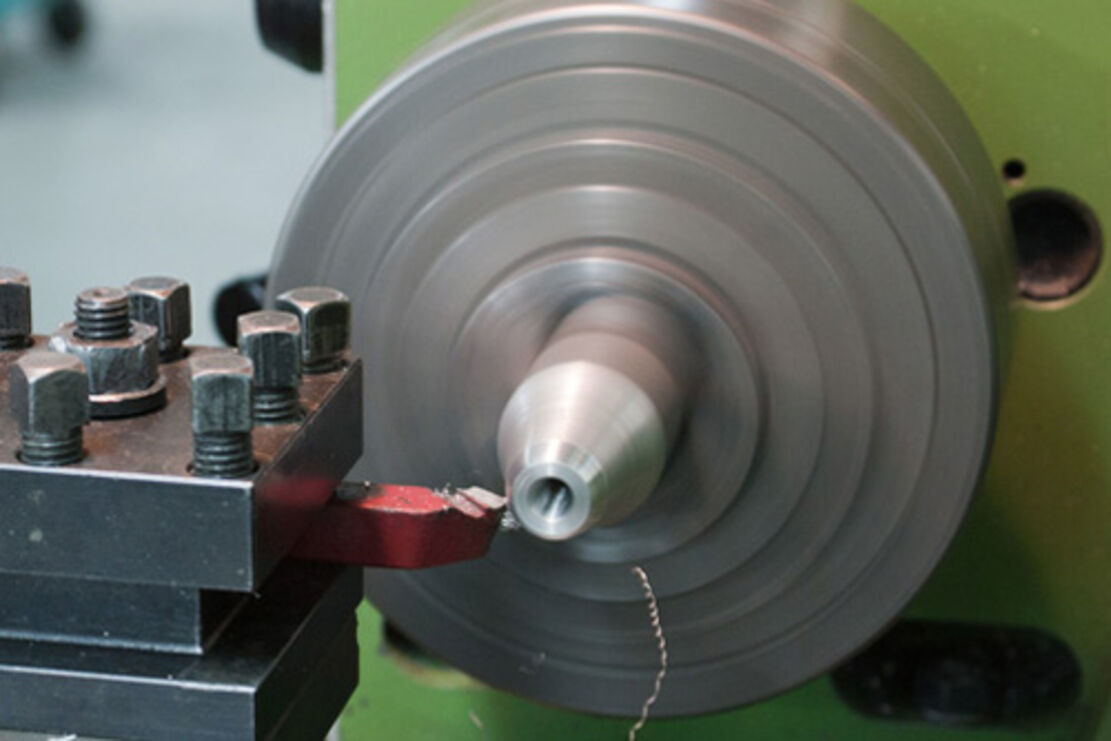

With a size of approx. 250 m² floor space, the model building workshop is equipped with the usual metalworking machines. These include a lathe, edging bench and roller. Various joining processes can also be carried out. In addition to brazing and soft soldering, welding techniques such as TIG and MAG welding are available for this purpose.