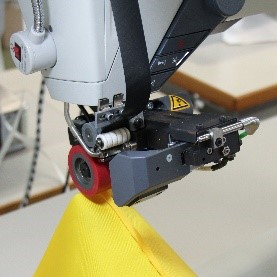

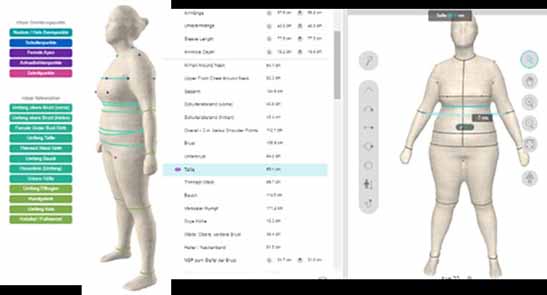

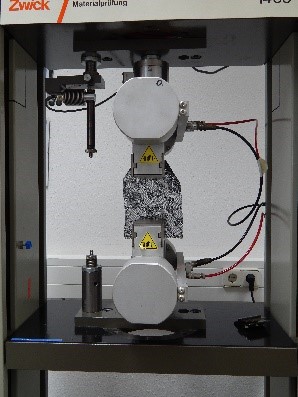

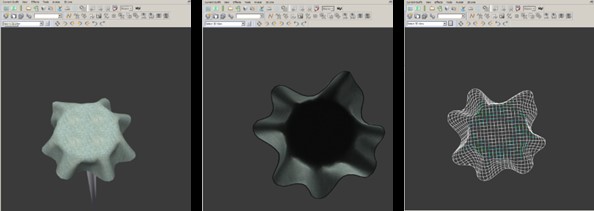

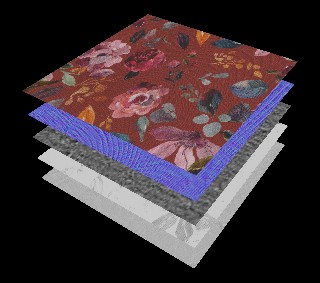

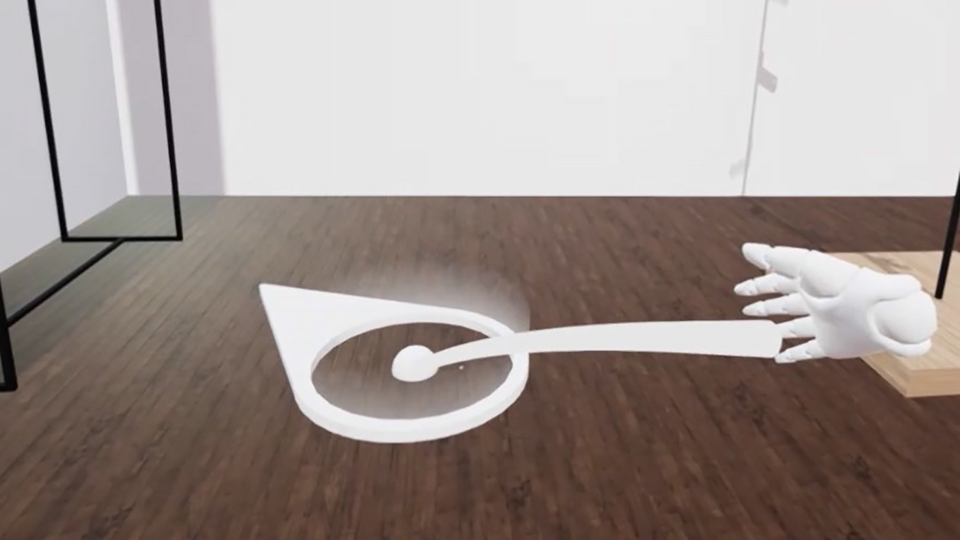

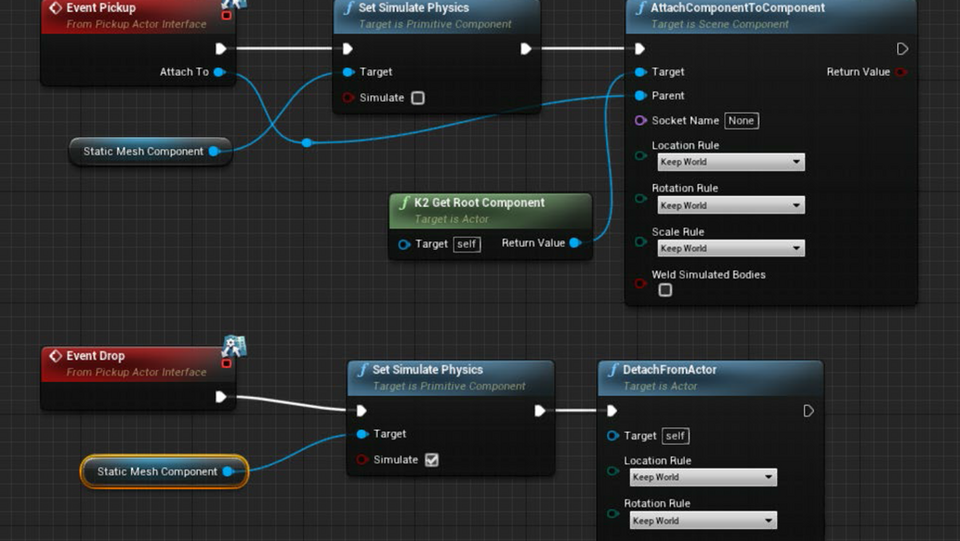

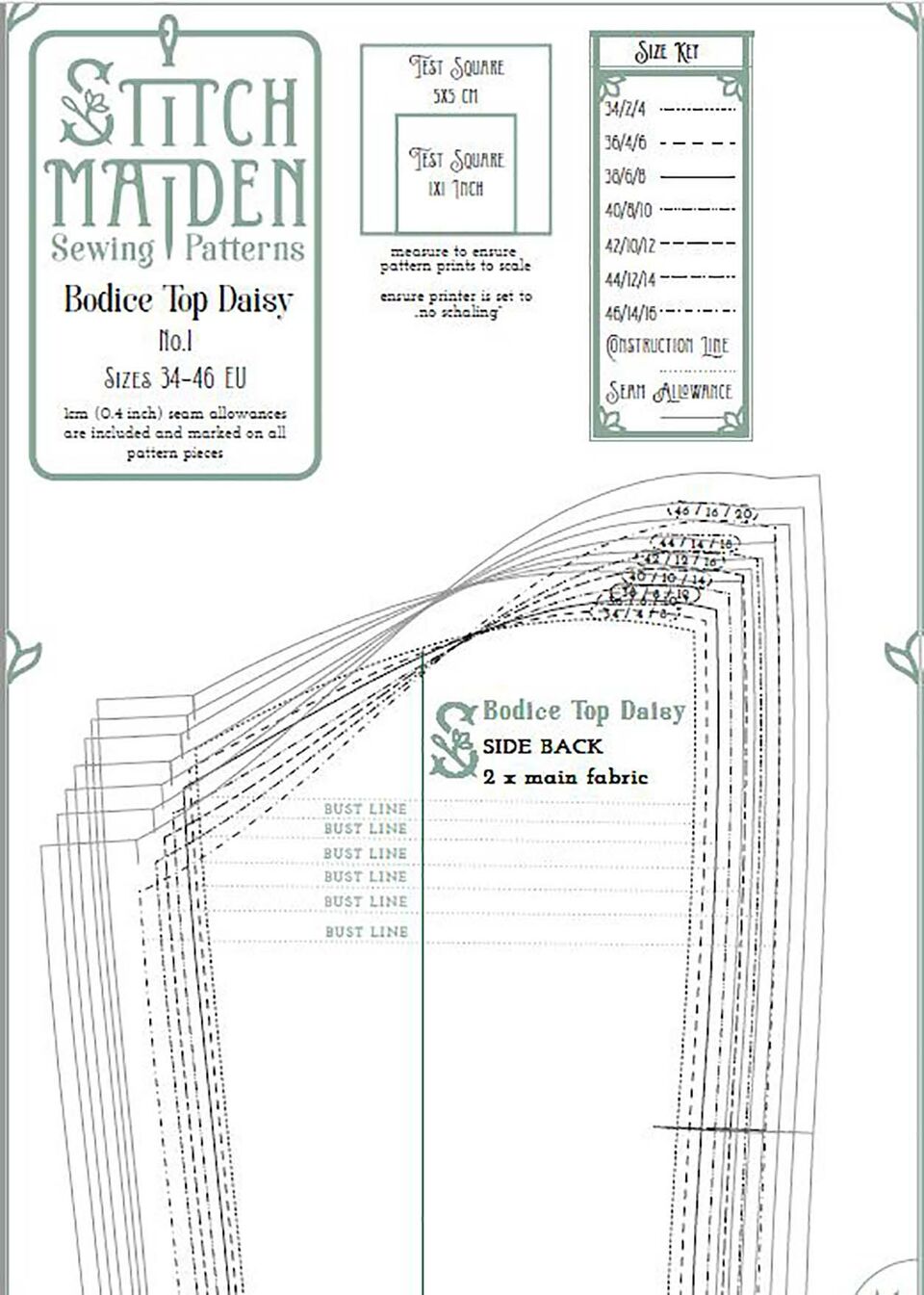

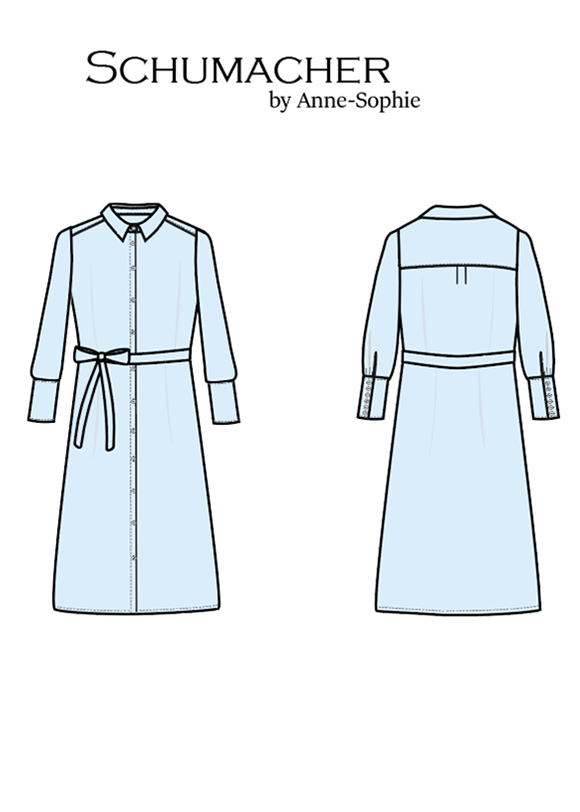

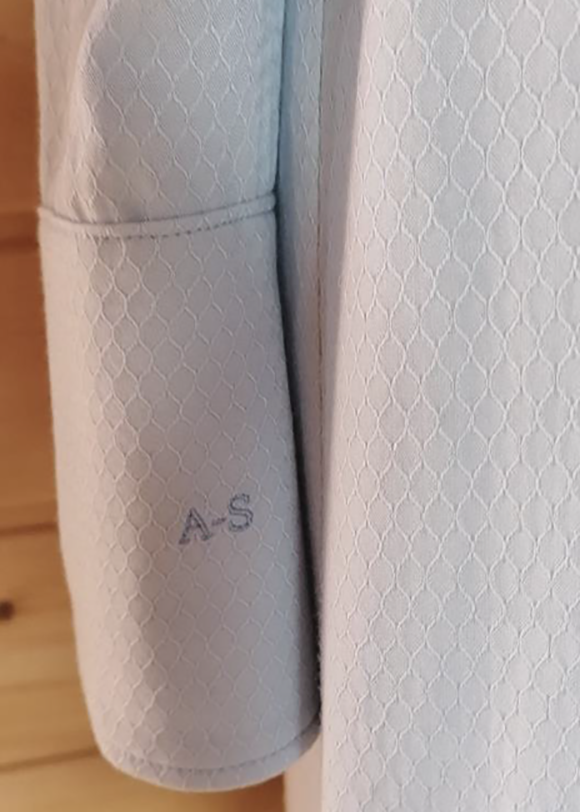

With the Clothing major, students qualify for the development and implementation of product and process innovations. Extensive knowledge of future-oriented virtual product development with all the building blocks of 3D CAD technologies is taught. Innovative production methods such as new seam-forming joining technologies as well as methods for integrating mass customization in the development and production processes expand the competencies in the clothing technology field. The development and production of functional clothing is demanding and requires a sound knowledge of the special features of the production process. This aspect is addressed in advanced courses on functional textiles and supplemented by practical applications.