Lectures

Math I for Sciencer

Reaction Engineering I

Reaction Engineering II

Catalysis

Surface Analysis

Sustainability in industrial chemistry

Physical Chemistry I

internships

Physical Chemistry

Reaction Engineering I

Advanced practical course

Lectures

Math I for Sciencer

Reaction Engineering I

Reaction Engineering II

Catalysis

Surface Analysis

Sustainability in industrial chemistry

Physical Chemistry I

internships

Physical Chemistry

Reaction Engineering I

Advanced practical course

Topics for degree or project assignments will be assigned at any time for the following specialisations:

- Heterogeneous Catalysis

- Reaction Engineering

- Sustainability in industrial chemistry

selected examples:

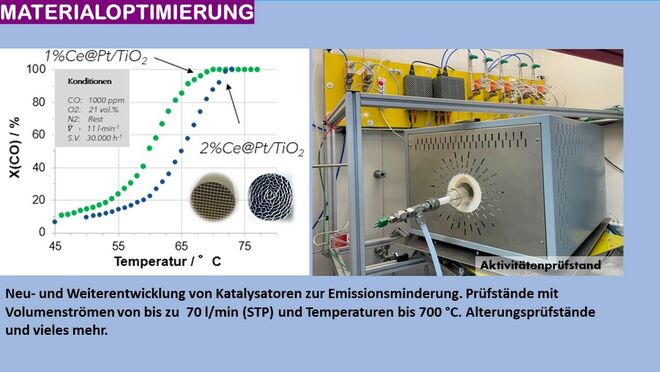

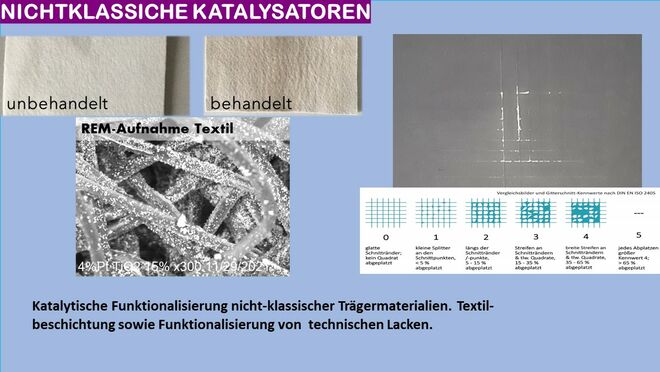

1. development of precious metal-minimized catalysts for emission reduction

2. development of exhaust gas catalysts based on renewable raw materials

3. development of catalytic evaporators

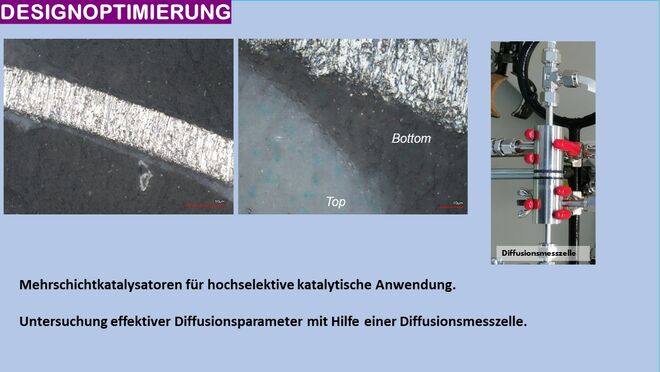

4. development and design of dual-layer catalysts for selective oxidation reactions

5. technical evaluation of microreactors and micromixers for use in synthesis and process design

6. development of a photoreactor for gas phase oxidation

7. development of an IR transmission cell for measurements at T > 350 °C

Professional career

since 09/2020 Professor for Technical Chemistry at The Hochschule Niederrhein

08/2019 - 07/2020 Development engineer at Altenburger Maschinen Jäckering GmbH

06/2017 - 07/2019 Head of R&D at Emission Partner GmbH & Co. KG

04/2013 - 03/2017 Research group leader exhaust gas aftertreatment at TU Freiberg

Adlerstr. 32

by arrangement

Looking for the right counseling center? Our counseling navigator will help you find it.