The area of specialisation "Textile Technologies" trains you as a junior engineer for the diverse technical and business tasks in the textile industry. The very practical emphasis / orientation of the courses includes material science, textile production and related quality analysis. You will also be introduced to the contents of the organization of a global industrial and commercial enterprise in the textile sector.

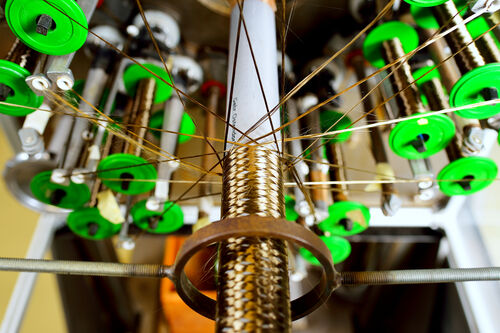

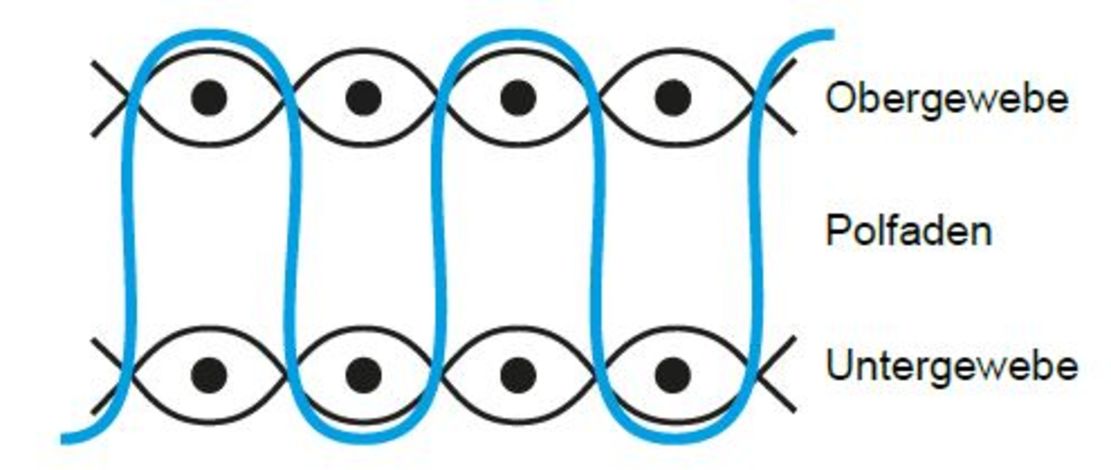

The specialisation "Textile Technologies" focuses on the creation of textile products. You will learn the individual steps of the textile chain in detail, both in theory and practice, and deal intensively with the design and manufacture of the many different types of products. These include yarns, flat and round braids, broad and narrow fabrics, knitted fabrics and nonwovens. Furthermore, you will learn how the textile products are finished or functionalized by means of dyeing and printing as well as finishing and coating. In the same way, they learn how the textile goods are then processed into finished end products by means of manufacturing and processing techniques in the ready-to-wear sector. Another specialisation of the Textile Technologies apprenticeship is computer-aided design. Here you will be qualified within the digital development and Engineering Design and Development of textile products using industrial CAD programs. Subsequently, you will then convert your designs into a real product.

In addition to the knowledge of Textile Technologies, it is important for your later professional life to develop a business understanding of these processes. For this reason, you will also gain insight into the application of management processes to the national and global textile industry. Foundation courses in business administration and economics, human resource management, marketing and logistics as well as intercultural management will play a role. In parallel, the aspect of responsible handling of sustainability and environmental management will accompany you.

We are looking forward to meeting you!