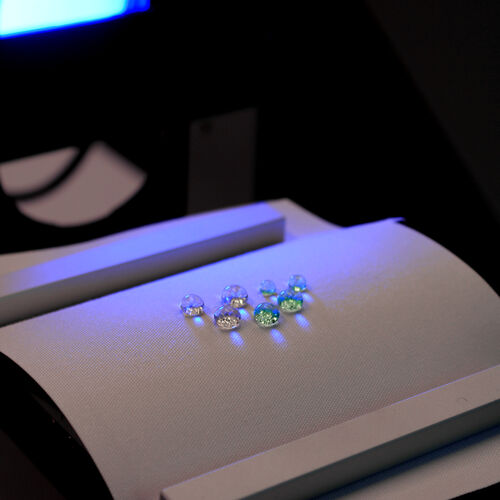

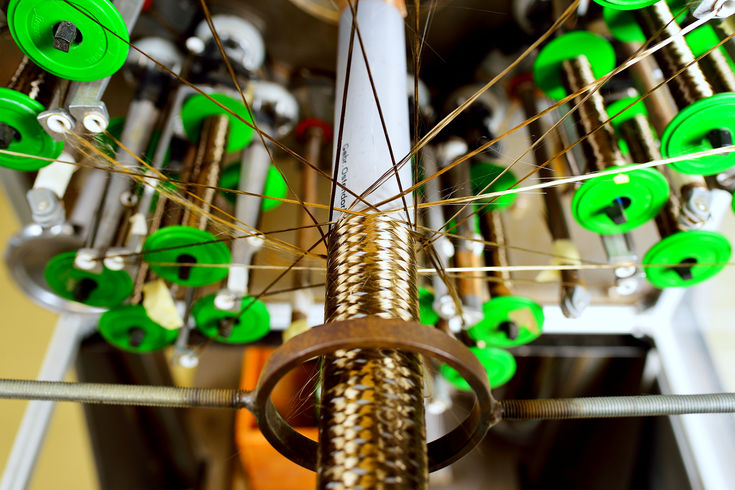

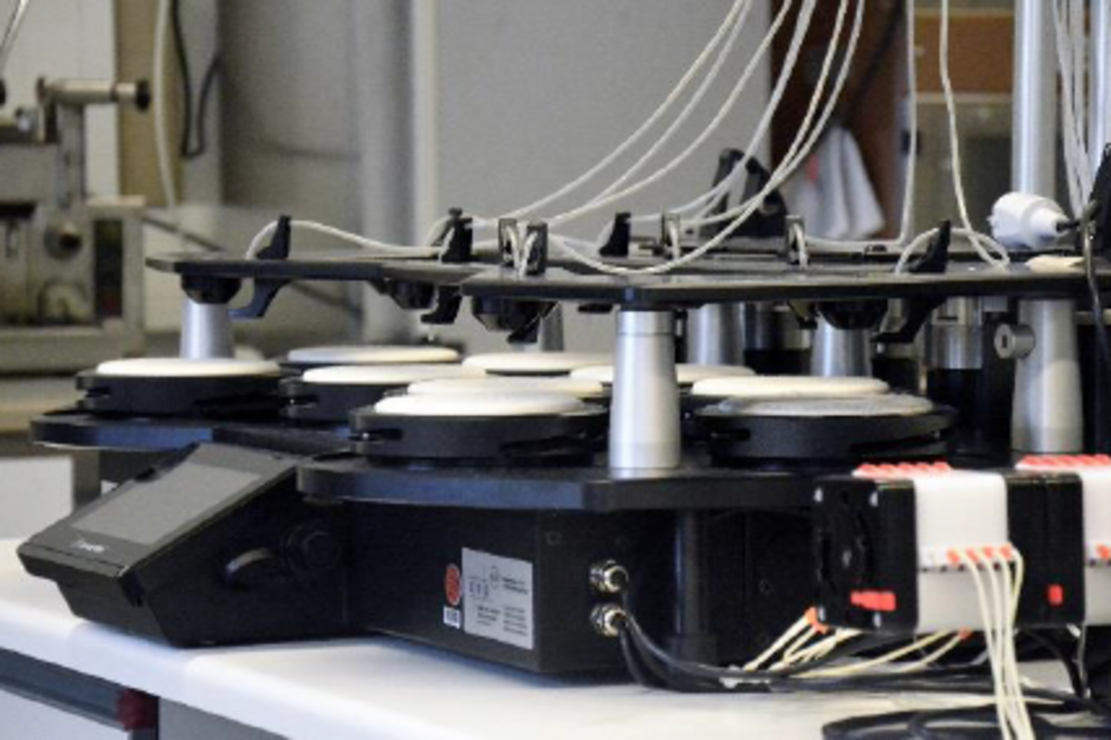

The Textile field of study is aimed at students who wish to deepen and expand their knowledge in both the natural sciences and textile technology. Skills are taught to create intelligent, innovative processes as well as textile products and to accompany them until they are ready for production. The textile area in the Master's degree programme Textile Products is an ideal link between the two other majors Design and Clothing and spans the entire textile value chain, starting with the production of fibres and textiles, through their finishing, to their utilization. In order to meet today's requirements for the sustainable development of textile products, practical orientation is given in the studies to the possibilities of avoiding environmental pollution and recycling used textiles. In addition, modern analysis procedures, methods for the functionalization of textiles and the application of advanced manufacturing processes are taught in the technical area.

The application and design of integrated and lived management systems establishes the reference to the organization and control of technical processes.