O. Kyzymchuk, Y. Kyosev, C. Richter, E. Bendt

Reference Module in Materials Science and Materials Engineering, Chapter: Mechanics of Knitted Fabrics

Elsevier Inc., 2023

doi.org/10.1016/B978-0-323-90646-3.00018-6

M.T. Hoque, K. Klinkhammer, B. Mahltig

Finishing of cotton and polyester fabrics using chitosan-containing recipes

Bulletin of Vitebsk State Technological University, 2023, 3(46), 84-91.

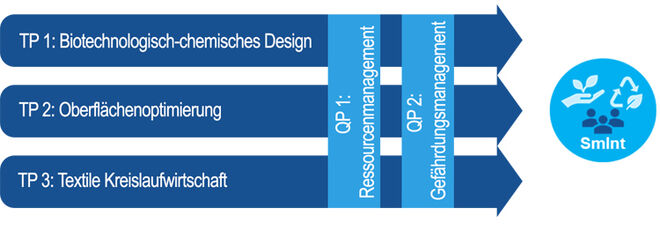

E. Lempa, A. Memisoglu, M. Rabe, M.Eigenstetter

Innovative finishing processes and an effective chemicals management for a safe

and sustainable textile industry

Book of Abstracts, P88, p. 233, Aachen-Dresden-Denkendorf International Textile Conference, ADDITC 2023, 30.11. - 01.12.2023, Dresden

M. T. Hoque, M. Eigenstetter

Jute - the golden fiber with excellent opportunities

Book of Abstracts, P87, p. 232, Aachen-Dresden-Denkendorf International Textile Conference, ADDITC 2023, 30.11. - 01.12.2023, Dresden

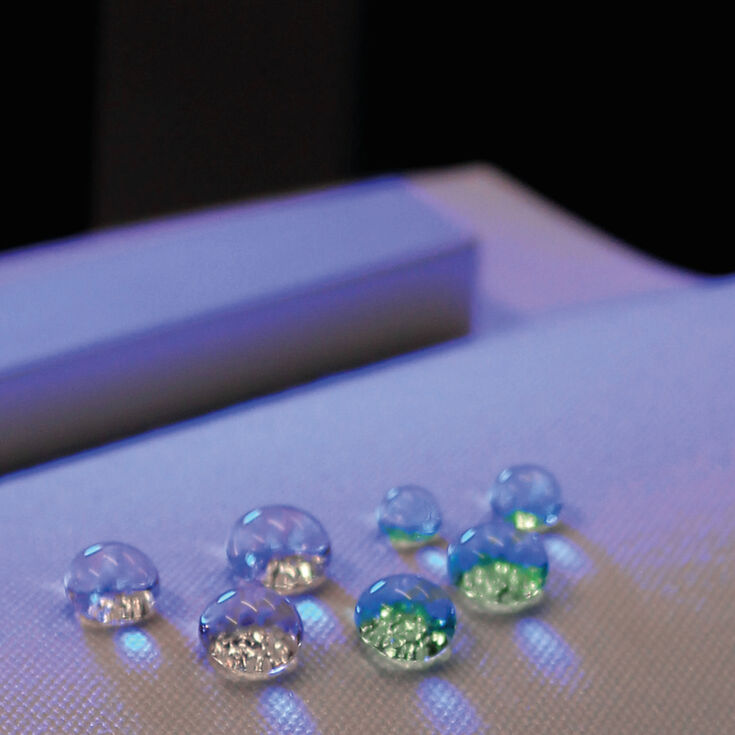

C. Richter, K. Klinkhammer, E. Bendt, C. Cherif

Water pressure difference test system for investigating the porosity of textile surfaces

Book of Abstracts, P86, p. 231, Aachen-Dresden-Denkendorf International Textile Conference, ADDITC 2023, 30.11. - 01.12.2023, Dresden

L. Blanckart, K. Ratovo, A. Rahaman, A. Abomohra, K.von Schwartzenberg, L.-J. Liebscher, M. Ecke, S. Matthes, N. Pathil, K. Knufmann, J. Ullmann, S. Hirschmüller, B. Sebastian, B. Mahltig, E. Bendt

Aquatic natural fibers as new raw material with potential for the textile industry

Book of Abstracts, P85, pp. 230, Aachen-Dresden-Denkendorf International Textile Conference, ADDITC 2023, 30 Nov - 01 Dec 2023, Dresden

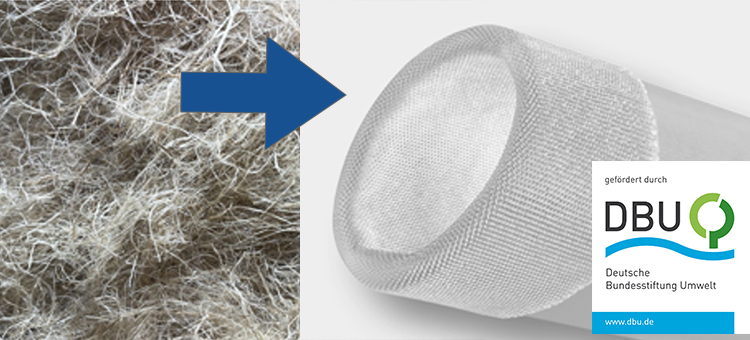

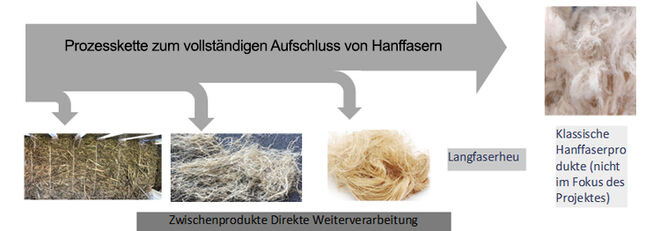

C. Heil, D. Pattberg, H. Dagdeviren, K. Ratovo, J. Lewin, C. Richter, K. Klinkhammer, L. Blanckart, T. Bache, S. Grobe, T. Engel, D. Strahl-Schäfer, T. Weide, B. Mahltig, E. Bendt

Tradition meets innovation - hemp fibres as an opportunity for new, sustainable

textile products with a regional value chain

Book of Abstracts, P84, p. 229, Aachen-Dresden-Denkendorf International Textile Conference, ADDITC 2023, 30.11. - 01.12.2023, Dresden

L. Hellweg, Y. Kyosev, M. Beer

Safety in fully autonomous passenger cars - Analysis of the current and new requirements for textile-based restraint system

Book of Abstracts, P82, p. 228, Aachen-Dresden-Denkendorf International Textile Conference, ADDITC 2023, 30.11. - 01.12.2023, Dresden

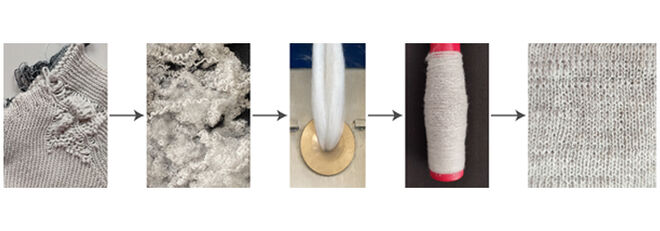

M. Taubert, H. Dagdeviren, T. Weide, K. Klinkhammer, D. Pattberg, C. Heil, E. Bendt

Alpax I + II - Yarn-, fabric- and product development for outdoor clothing made of alpaca fibers

Book of Abstracts, P82, p. 227, Aachen-Dresden-Denkendorf International Textile Conference, ADDITC 2023, 30 November - 1 December 2023, Dresden

R. Brendgen, K. Waletzke, K. Mengler, J. Schüssler, E. Nannen, A. Schwarz-Pfeiffer

Market growth vs. skilled labour shortage: The role of higher education in smart textiles

Book of Abstracts, P81, p. 226, Aachen-Dresden-Denkendorf International Textile Conference, ADDITC 2023, 30.11. - 01.12.2023, Dresden

K. Klinkhammer, M. T. Hoque, H. Hohenbild, L. Elze, H. Teshay, B. Mahltig

Functionalization of technical textiles with chitosan

Book of Abstracts, P80, p. 225, Aachen-Dresden-Denkendorf International Textile Conference, ADDITC 2023, 30.11. - 01.12.2023, Dresden

J. Bulthaupt, A. Tabakovic, L. Hellweg, M. Beer

Application of artificial intelligence in the field of textiles - Development of a transdisciplinary teaching concept for textile technology students

Book of Abstracts, P79, p. 224, Aachen-Dresden-Denkendorf International Textile Conference, ADDITC 2023, 30.11. - 01.12.2023, Dresden

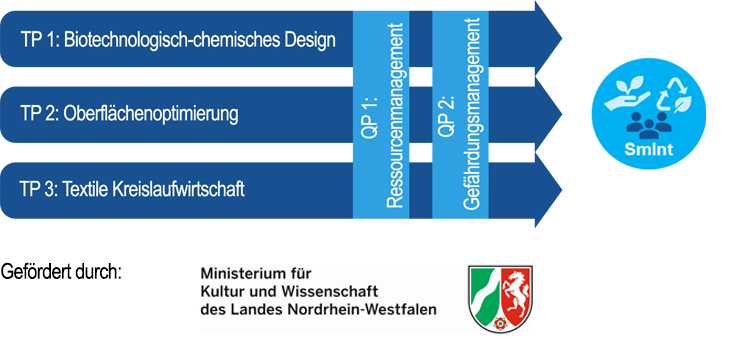

I. Hofmann, A. Glogowsky, M. C. Reuters, S. Krause, J. Krayer, M. Rabe, U. Schwaneberg

Cooperation platform KlarTEXt for the dynamisation of a sustainable and transformative textile economy

Book of Abstracts, P78, p. 223, Aachen-Dresden-Denkendorf International Textile Conference, ADDITC 2023, 30.11. - 01.12.2023, Dresden

T. H. Mai, T. Grethe, B. Mahltig

Natural dyeing of cotton with extract from colour wood

Book of Abstracts, P77, p. 222, Aachen-Dresden-Denkendorf International Textile Conference, ADDITC 2023, 30.11. - 01.12.2023, Dresden

I. Hofmann, I. Singer, S. Kolbe, M. Rabe

Increased surface functionality through enzymatic treatments of bio-based and conventional polyesters

Book of Abstracts, P76, p. 221, Aachen-Dresden-Denkendorf International Textile Conference, ADDITC 2023, 30.11. - 01.12.2023, Dresden

E. Heine, R. Gartzen, A. Herrmann, R. Lütticken, I. Hofmann, S. Kolbe, R.Groten

ProSwabs - Efficient swab system for precise laboratory diagnostics and consecutively specific antibiosis and disinfection

Book of Abstracts, P70, p. 215, Aachen-Dresden-Denkendorf International Textile Conference, ADDITC 2023, 30.11. - 01.12.2023, Dresden

B. Quattelbaum, M. Streit, C. Breckenfelder

5G mobile user textile AR experience - the virtual dressing room as an opportunity for stationary and online trade 5G mobile user textile AR experience

Die virtuelle Ankleidekabine als Chance für den stationary und den Online-Handel

Session: "Technology Transfer "Form Idea to Practice""

Book of Abstracts, pp. 79f, Aachen-Dresden-Denkendorf International Textile Conference, ADDITC 2023, 30.11. - 01.12.2023, Dresden

B. Mahltig

Comparison of conventional and digital lectures and examinations with respect to the conditions after COVID 19 period- an example for a bachelor lecture on textile finishing

Communications in Development and Assembling of Textile Products - CDATP, 2023, 4, 284-293

B. Quattelbaum, C. Steinem, M. Neumann

Data-Informed Design Process for SME: A Streamlined Validation and Prediction Approach for Customer Perception of Innovative Material Prototypes

Proceedings of the ASME 2023 - International Mechanical Engineering Congress & Exposition®- IMECE®, Volume 2: Advanced Design and Information Technologies, V002T02A003, New Orleans Ernest N. Morial Convention Center, New Orleans, LA, USA, 29 October - 2 November 2023

Publisher: American Society of Mechanical Engineers

Paper No: IMECE2023-112222

https://doi.org/10.1115/IMECE2023-112222

P. Holderied, M. O. Weber, M.-A. Bueno

New weft knitting process: Morphological, physical and mechanical characterisation of the innovative knitted fabrics.

Journal of Engineered Fibers and Fabrics 18, article 15589250231205184. DOI: 10.1177/15589250231205184.

https://journals.sagepub.com/doi/10.1177/15589250231205184

L. Blanckart, K. Ratovo, B. Mahltig, E. Bendt

Aquatic natural fibres as a new raw material with potential for the textile industry

Melliand Textilberichte 4/2023, Fasern & Garne, p. 20ff

L. Vossebein

The strength of the network: pooling expertise for applied hygiene

Hygiene & Medizin, Volume 48, 9/2023

M.T. Hoque, K. Klinkhammer, B. Mahltig

HT process for treatment of PET fabrics with chitosan containing recipes

Communications in Development and Assembling of Textile Products - CDATP, 2023, 4, 222-230

https://journals.qucosa.de/cdatp/article/view/124

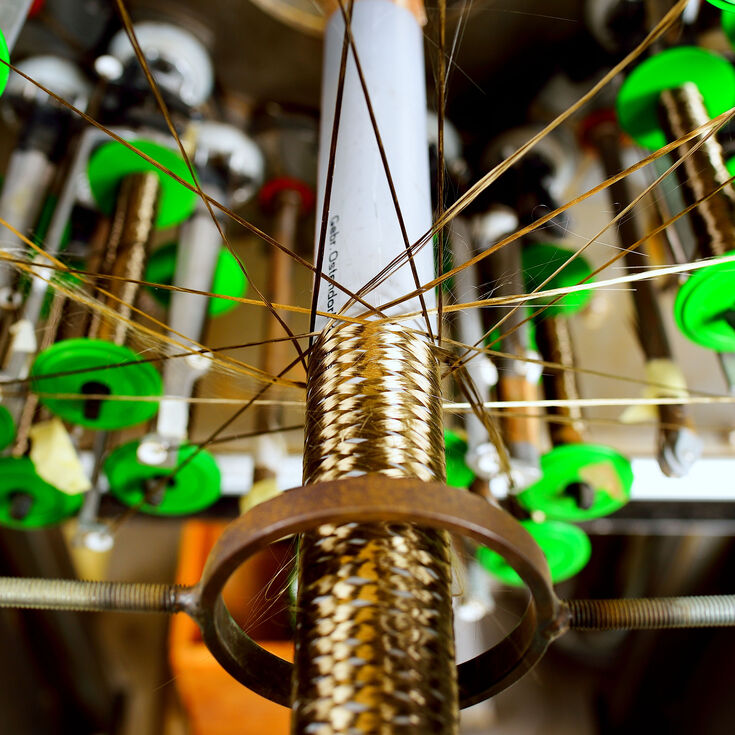

T. Junge, R. Brendgen, C. Graßmann, T. Weide, A. Schwarz-Pfeiffer

Development and Characterization of Hybrid, Temperature Sensing and Heating Yarns with Color Change

MDPI, Sensors 2023 , 23(16), 7076

https://www.mdpi.com/1424-8220/23/16/7076

K. Stylidis, B. Quattelbaum, C. Diels, A. Braun, F. Konrad, R. Söderberg

Perceived Comfort of Car Seats: A Research Methodology to Visual Cues Evaluation.

In: A. Chakrabarti, V. Singh (eds) Design in the Era of Industry 4.0, Volume 3. ICORD 2023. Smart Innovation, Systems and Technologies, vol 346. Springer, Singapore.

https://doi.org/10.1007/978-981-99-0428-0_21

Print ISBN978-981-99-0427-3

Online ISBN978-981-99-0428-0

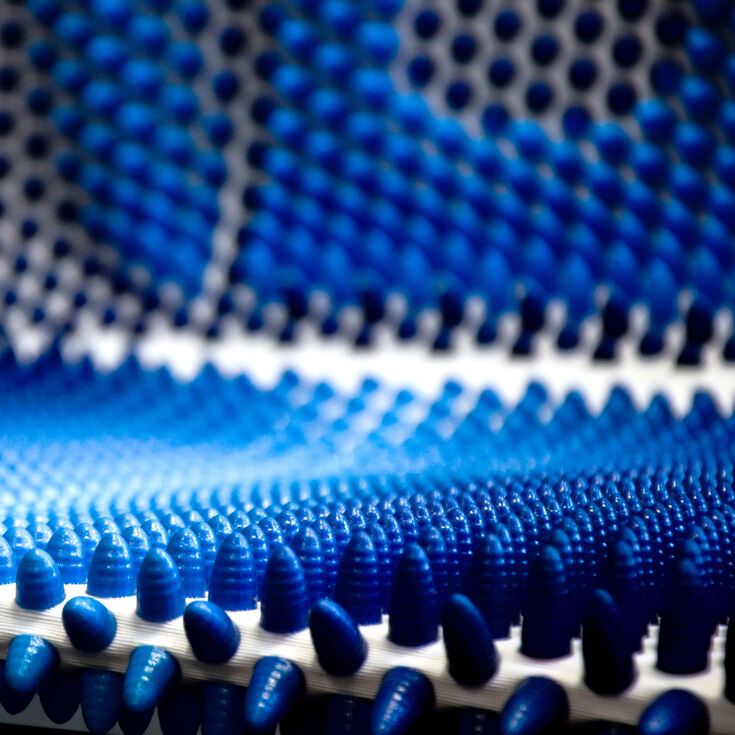

A. Glogowsky, M. Korger, M. Rabe

Influence of print settings on conductivity of 3D printed elastomers with carbon-based fillers

Progress in Additive Manufacturing Vol. 8, August 2023

DOI: 10.1007/s40964-023-00483-y

J. Bulthaupt, A. Tabakovic, L. Hellweg, M. Beer

Artificial intelligence in textile - transdisciplinary teaching concept for students in the field of textile technology

Digital Poster Presentation, ITMA 2023 - Textile & Garment Technology Exibition, 08. - 14.06.2023, Milan, Italy

M.-E. Ostheller, N. K. Balakrishnan, K. Beukenberg, R. Groten, G. Seide

Pilot-Scale Melt Electrospinning of Polybutylene Succinate Fibre Mats for a Biobased and Biodegradable Face Mask

MDPI, Polymers 2023, 15, 02936

Abstract: https://www.mdpi.com/2073-4360/15/13/2936

PDF-Version: https://www.mdpi.com/2073-4360/15/13/2936/pdf

M.T. Hoque, T. Benrui, T. Grethe, B. Mahltig

Evaluation of chitosan based pretreatment for cotton and linen dyeing with direct dyes and reactive dyes

Communications in Development and Assembling of Textile Products - CDATP, 2023, 4, 187-200.

E. Lempa, S. Brandt, O. Heß, B. Mahltig, M. Rabe, I. Singer, S. Wagner

ITMA 2023 - between taking a deep breath and holding your breath

ITMA 2023 - between taking a deep breath and holding your breath

Melliand 06/2023, p. 41-43

A. Memisoglu, E. Lempa, M. Eigenstetter

Innovative Finishing Processes and an Effective Chemicals Management for a Safe and Sustainable Textile Industry - Practical Insights from the German-Indonesian Project EnaTex

Poster at Textile Colourants and Chemicals Forum, ITMA 2023 - Textile & Garment Technology Exibition, 09.06.2023, Milan, Italy

A. Glogowsky, A. Korn, B. Rau, M. Rabe

Use of 3D printing technology for the production of thin layers. Digital coating of textiles.

Poster Presentation ITMA Innovator Xchange, ITMA 2023 - Textile & Garment Technology Exibition, 08. - 14.06.2023, Milan, Italy

Poster available online https://virtual.oxfordabstracts.com/#/event/3214/poster-gallery/grid?sort=titles¤t=176.

B. Mahltig, T. Leisegang, M. Jakubik, H. Haufe

Hybrid Sol-Gel Materials for Realisation of Radiation Protective Coatings - a review with emphasis on UV protective materials

Journal of Sol-Gel Science & Technology, 2023, 107, 20-31.

E. Bendt, M. Rabe, S. Kolbe, S. Küppers, S. Brandt, J. Meyer, M. Obermann, K. Ratovo

Micro/nanoplastics

Book chapter 19 [Toxicology/safety/ecological toxicity and environmental impact] in: Particle Technology and Textiles - Review of applications (Edt.: J. Cornier, F. Pursche)

2nd Edition, Walter de Gruyter GmbH, Berlin, 2023, pp. 373ff

ISBN: 978-3-11-0670769

doi.org/10.1515/9783110670776-202

B. Mahltig

Finishing of textile materials

Book chapter 3 [Fillers in Fibers and textiles] in: Particle Technology and Textiles - Review of applications (Edt.: J. Cornier, F. Pursche)

2nd Edition, Walter de Gruyter GmbH, Berlin, 2023, p.45ff

ISBN: 978-3-11-0670769

doi.org/10.1515/9783110670776-202

E. Bendt, B. Mahltig

Textile sun protection with skin care upgrade

Masche 2023, Issue 1 - Worth knowing, p. 25

K. Klinkhammer, P. Weskott, K. Ratovo, M. Krieg, E. Bendt, B. Mahltig

Transmission Reduction for UV and IR Radiation with Dyed Lyocell Knitted Textiles

Applied Sciences, 2023, 13, 5432.18 pages

doi.org 10.3390/app13095432

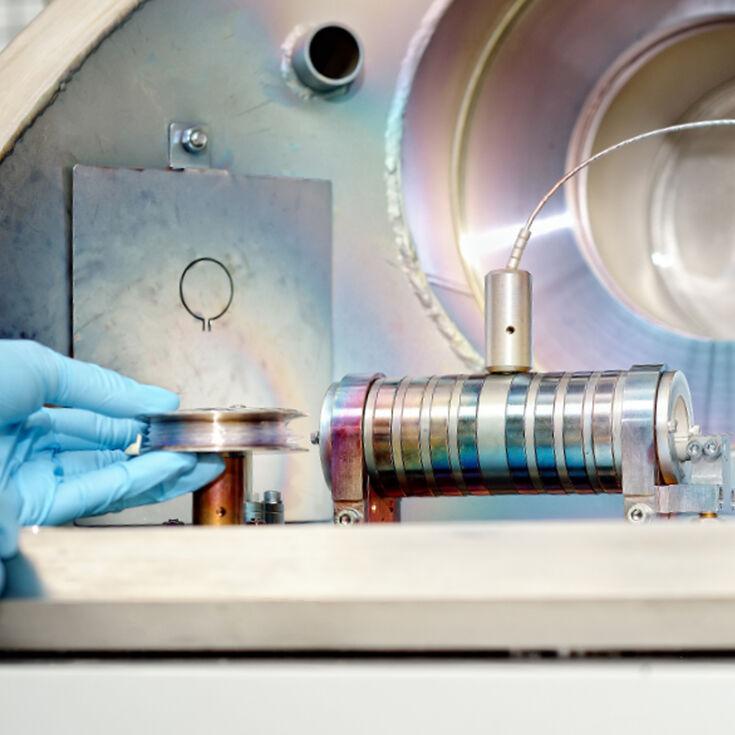

H. Lichtenberg, C. Elfenkemper, B. Mahltig, A. Prange, J. Hormes, W. Klysubun

Synchrotron radiation for the analysis of inorganic fibres - especially basalt fibres

Technical Textiles, 2023, 66, 22-24.

H. Lichtenberg, C. Elfenkemper, B. Mahltig, A. Prange, J. Hormes, W. Klysubun

Synchrotron radiation for the analysis of inorganic fibres - especially basalt fibres

Technical Textiles, 2023, 66, 22-24.

N.S.L. Dissanayake, M.A. Pathirana, N.D. Wanasekara, B. Mahltig, G.K. Nandasiri

Removal of Methylene Blue and Congo Red Using a Chitosan-Graphene Oxide Electrosprayed Functionalized Polymeric Nanofiber Membrane

Nanomaterials, 2023, 13, 1360, 22 pages.

L. Vossebein, S. Anton-Katzenbach

A differentiated view of laundry from retirement homes

Health & Care Management, Issue 2/2023, Volume 14, pp. 60-6

L. Vossebein, S. Anton-Katzenbach

Textiles from retirement and nursing homes - interpretative scope

R+W Textilservice, Issue 4, April 2023, B7011, 122 Volume, pp. 34-36

S. Schick, R. Groten, G. Seide

Performance Spectrum of Home-Compostable Biopolymer Fibers Compared to a Petrochemical Alternative

MDPI, Polymers 2023, 15, 01372

Abstract: https://www.mdpi.com/2073-4360/15/6/1372

PDF-Version: https://www.mdpi.com/2073-4360/15/6/1372/pdf

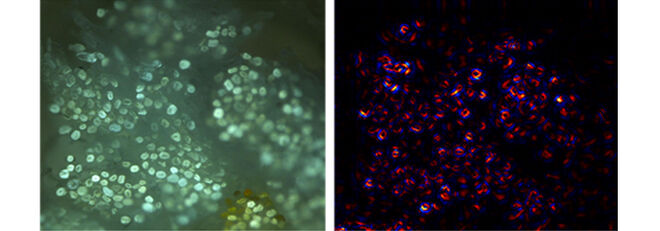

B. Mahltig, V. Ernst, L. Schröder

Exemplarily view on selected fluorescence textile products

Communications in Development and Assembling of Textile Products - CDATP, 2023, 4, 61-69.

W. Yuan, T. Grethe, B. Mahltig

Sol-gel coatings with the fluorescence dye Rhodamine B for the optical modification of cotton

Communications in Development and Assembling of Textile Products - CDATP, 2023, 4, 1-17.

J. Klausmann, T. Mutschler, P. Holderied, L. Streitenberger, M. O. Weber, O. Kyzymchuk

ITMA 2023: Trends and innovations in warp knitting

Melliand Textilberichte 4/2023, p. 34-37

J. Klausmann, T. Mutschler, P. Holderied, L. Streitenberger, M. O. Weber, O. Kyzymchuk

ITMA 2023: Trends and novelties in warp-knitting

Melliand International 4/2023, pp. 24-27

P. Holderied, L. Streitenberger, T. Mutschler, J. Klausmann, M. O. Weber, O. Kyzymchuk

ITMA 2023: Innovations and trends in flat knitting

Melliand Textilberichte 4/2023, p. 38-41

P. Holderied, L. Streitenberger, T. Mutschler, J. Klausmann, M. O. Weber, O. Kyzymchuk

ITMA 2023: Innovations and trends in flat knitting

Melliand International 4/2023, pp. 28-31

A. Lindenbuß, J. Klausmann, P. Holderied, T. Mutschler, M. O. Weber

Investigation of Raschel packaging nets in the fruit and vegetable sector

Melliand Textilberichte, 2/2023, pp. 26-28

J. Klausmann, T. Mutschler, P. Holderied, D. Güther, T. Freitag, M. Hummel, M. Zeitler, O. van Neerven, M. O. Weber, C. Breckenfelder

Thermodynamic qualification of knitted spacer fabrics for use as insulation box insert in the context of refrigerated transport containers in the logistics sector

Communications in Development and Assembling of Textile Products, p. 18-26, Vol. 4 No. 1 (2023)

DOI: https://doi.org/10.25367/cdatp.2023.4.p18-26

online: https://journals.qucosa.de/cdatp/article/view/99

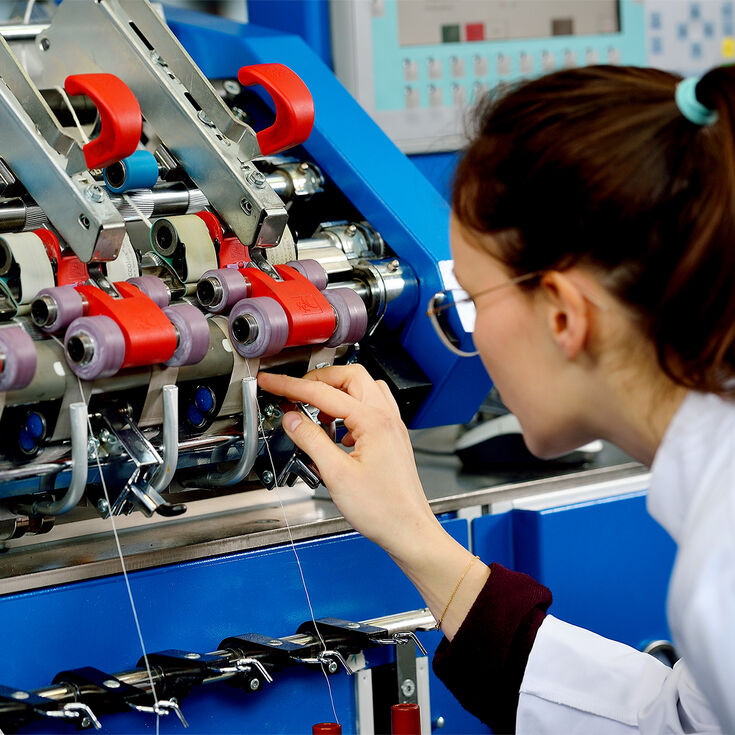

P. Holderied, T. Mutschler, S. Tresp, J. Klausmann, L. Streitenberger, M.-A. Bueno, M. O. Weber

Development of a new yarn supply for weft knitting machines to produce innovative knitwear

Communications in Development and Assembling of Textile Products, p. 51-60, Vol. 4 No. 1 (2023)

DOI: https://doi.org/10.25367/cdatp.2023.4.p51-60

online: https://journals.qucosa.de/cdatp/article/view/98

A. Dannehl, A. Buhr, A. Sanchez Leyton, L. Hellweg, M. Beer, L. Sabantina

Self-healing materials for potential use in textile and clothing applications

Communications in Development and Assembling of Textile Products (CDATP),2023, Vol. 5, No. 1, 27-41, DOI 10.25367/cdatp.2023.4.p27-41.

https://journals.qucosa.de/cdatp/article/view/92

M. A. Pathirana, N.S.L. Dissanayake, N.D. Wanasekara, B. Mahltig, G.K. Nandasiri

Chitosan-Graphene Oxide Dip coated Polyacrylonitrile-Ethylenediamine ElectrospunNanofibre Membrane for Removal of thedye stuffs Methylene Blue and Congo Red

Nanomaterials, 2023, 13, 498, 23 pages.