S. Gellner, A. Schwarz-Pfeiffer and E. Nannen, "Textile-Based Battery Using a Biodegradable Gel-Electrolyte", Proceedings 68, 1, 17 (2021).

https://doi.org/10.3390/proceedings2021068017

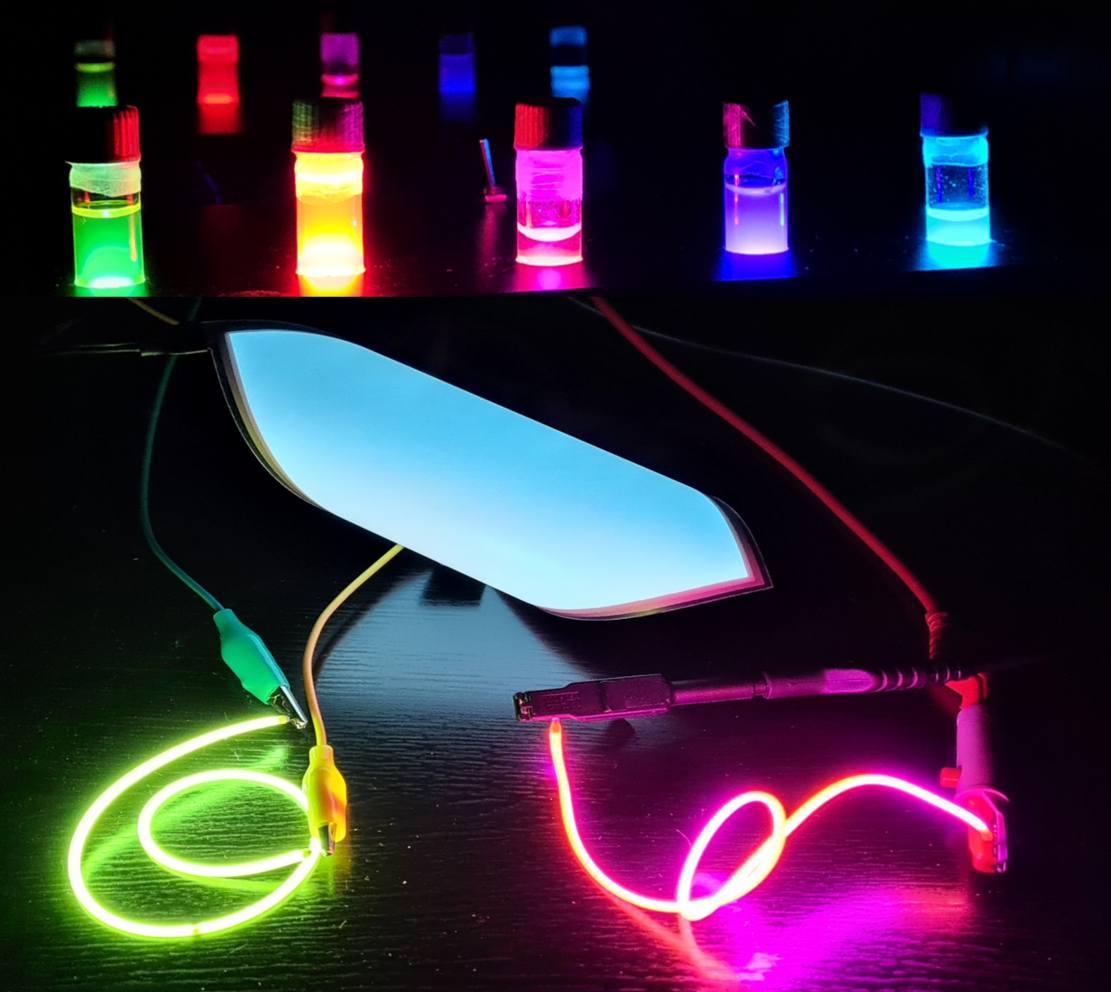

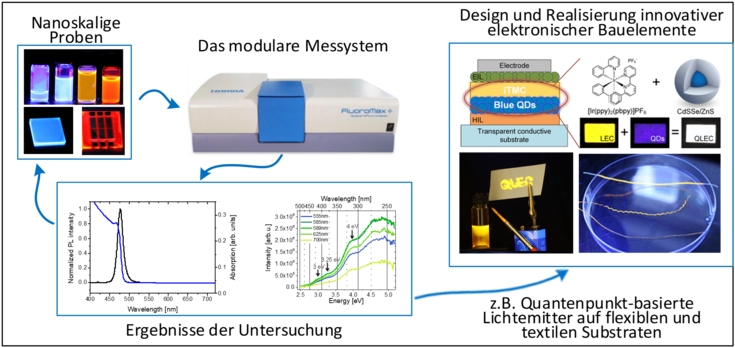

E. Nannen, J. Frohleiks and S. Gellner, "Light-Emitting Electrochemical Cells Based on Color-Tunable Inorganic Colloidal Quantum Dots", Adv. Funct. Mater. 30, 33, 1907349 (2020).

https://doi.org/10.1002/adfm.201907349

J. Frohleiks, S. Wepfer, G. Bacher and E. Nannen, "Realization of Red Iridium-Based Ionic Transition Metal Complex Light-Emitting Electrochemical Cells (iTMC-LECs) by Interface-Induced Color Shift", ACS Applied Materials & Interfaces 11, 25, 22612 - 22620 (2019).

https://doi.org/10.1021/acsami.9b07019

J. Frohleiks, S. Gellner, S. Wepfer, G. Bacher and E. Nannen, "Design and Realization of White Quantum Dot Light-Emitting Electrochemical Cell Hybrid Devices", ACS Appl. Mater. & Interfaces 10, 42637 (2018).

https://doi.org/10.1021/acsami.8b15100

J. Frohleiks, F. Wefers, S. Wepfer, A.-R. Hong, H. S. Jang and E. Nannen, "CuInS2 -based Quantum Dot Light-Emitting Electrochemical Cells (QLECs)", Adv. Mater. Technol. vol. 2, 11, 1700154 (2017).

https://doi.org/10.1002/admt.201700154

M. Di Marcantonio, J. E. Namanga, N. Gerlitzki, F. Vollkommer, A.-V. Mudring, G. Bacher and E. Nannen, "Green-Yellow Emitting Hybrid Light Emitting Electrochemical Cell", J. Mater. Chem. C, vol. 5, 12062 (2017).

https://doi.org/10.1039/C7TC02976D

S. Wepfer, J. Frohleiks, A.-R. Hong, H. S. Jang, G. Bacher and E. Nannen, "Solution-processed CuInS2 - based white QD-LEDs with mixed active layer architecture", ACS Appl. Mater. & Interfaces 9, 11224 (2017).

https://doi.org/10.1021/acsami.6b15660

S. Daumann, D. Andrzejewski, M. Di Marcantonio, U. Hagemann, S. Wepfer, F. Vollkommer, G. Bacher, M. Epple, and E. Nannen, "Water-free synthesis of ZnO quantum dots for application as electron injection layer in light-emitting electrochemical cells", J. Mater. Chem. C, vol. 5, 2344 (2017).

https://doi.org/10.1039/C6TC05571K

J. Frohleiks, S. Wepfer, Y. Kelestemur, V. H. Demir, G. Bacher and E. Nannen, "Quantum Dot / Light Emitting Electrochemical Cell Hybrid Device and Mechanism of its Operation", ACS Appl. Mater. Interfaces, vol. 8(37), 24692 (2016).

https://doi.org/10.1021/acsami.6b06833

E. Neshataeva, T. Kuemmell, G. Bacher, "Light emitting devices based on direct band gap semiconductor nanoparticles".(invited book chapter) In: "Inorganic Nanoparticles - New Frontiers of Research: Synthesis, Applications and Perspectives", book edited by Dr. Altavilla, CRC Press, ISBN: 97814398176122011 (2011).

E. Neshataeva, T. Kümmell, G. Bacher, A. Ebbers, "All-inorganic light emitting device based on ZnO nanoparticles". Appl. Phys. Lett. vol. 94(9), 091115 (2009).

https://doi.org/10.1063/1.3093675